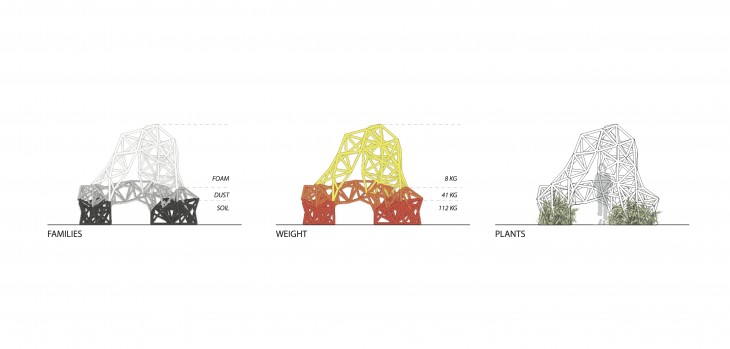

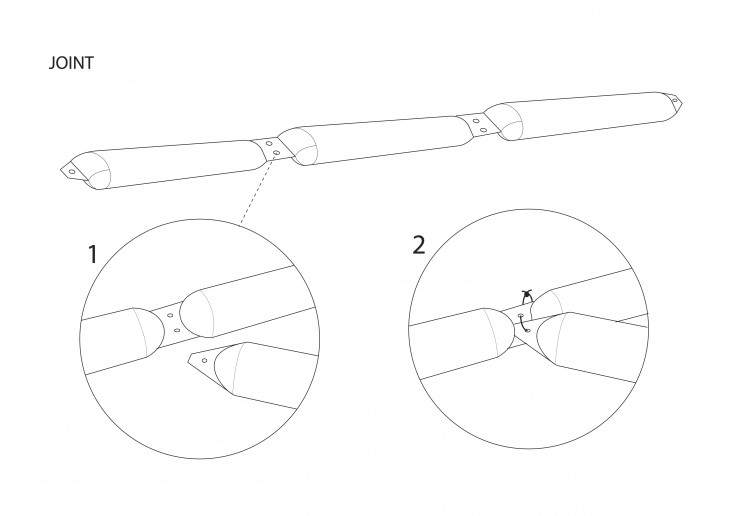

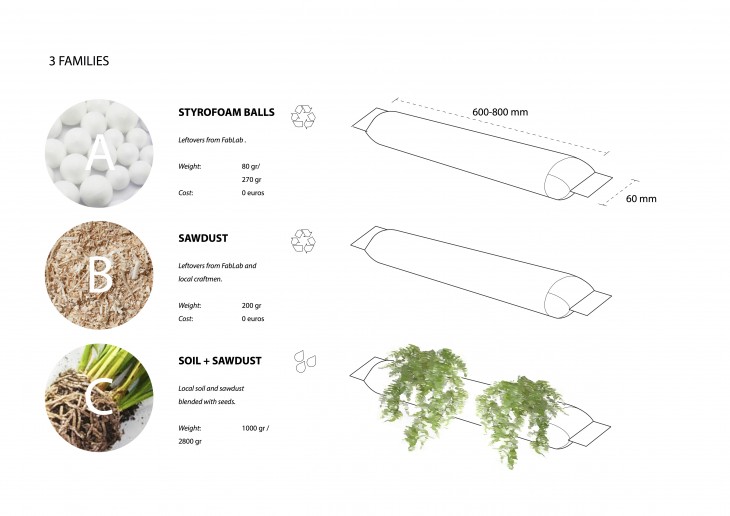

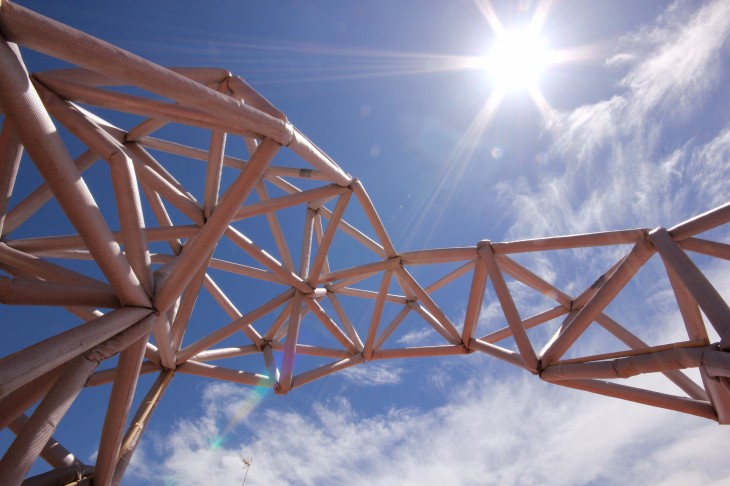

The Nubular lightweight structure is an exploration into an injection-based architecture. A homogenous building material, in this case a perforated PVC skin, is used to create tubes of custom lengths and angles, which are then filled with one’s material of choice depending on the chosen tube’s position within the overall structure. Given that the material filling is a key parameter in the behaviour of the elements, several tests were carried out to identify the optimal fillings and member lengths to avoid buckling. It was decided to fill the bottom most members with a soil and sawdust combination while the top is composed of lighter foam balls. Each tube length is split into 3 with a maximum part length of around 800mm and allowing for 50mm flat connection gaps in between and on the ends.

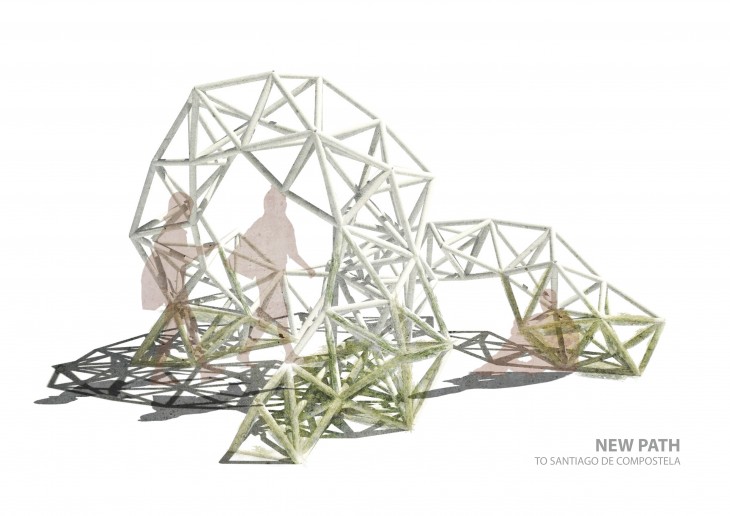

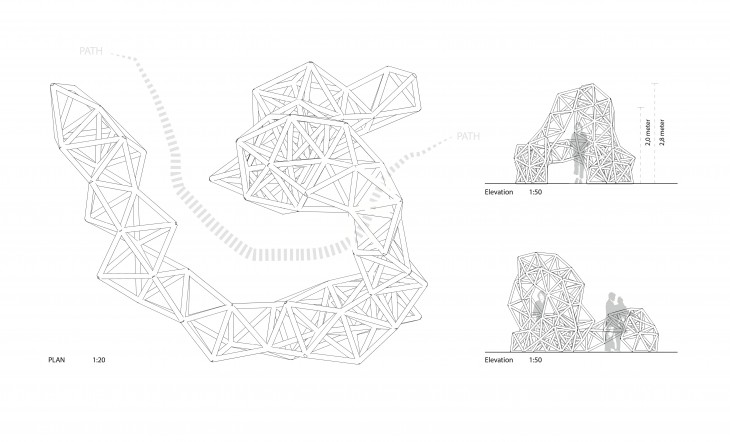

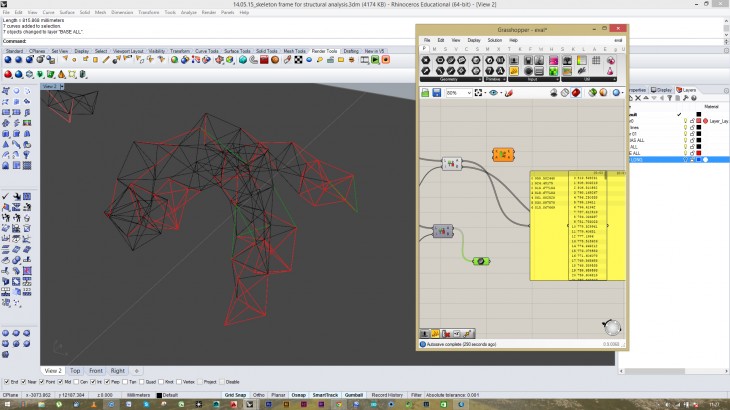

The overall shape was designed in Grasshopper using the Hoopsnake plugin. A original tetrahedron shape is drawn and hence follows the path of an arched curve, turning and repositioning itself in the process from the start of the path to the end. After this process, the geometry was manually pulled to the ground plane and specific 3-piece curves were extracted and drawn to ensure they stay under the 800mm limit. Each of these curves was separated as a layer and with lengths fed into another definition to directly produce laser cut files which included labels and welding line engravings.

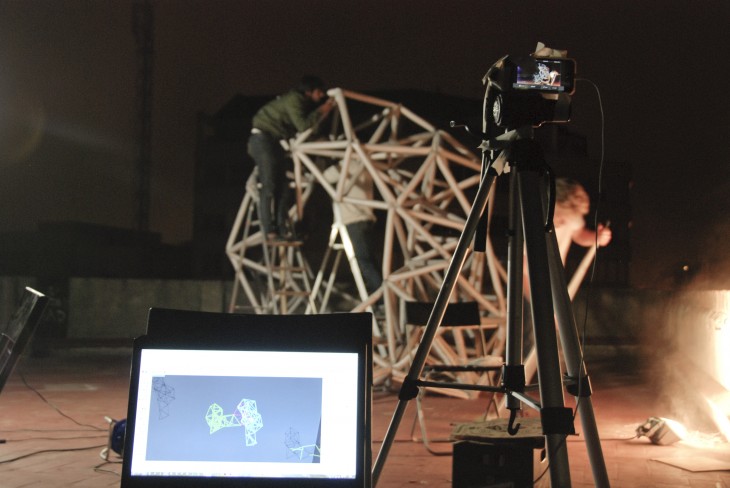

The fabrication process took about 3 full days. 78 custom lengths were laser cut, welded, filled, and holed at the junctions for connections with zip-ties. Construction took around 10 hours, as we constantly referred to the digital model to identify exact angles and connections of each length to the next. Ultimately the structure was a success and we learned a lot about the structural capabilities during the construction process. In parts where our soil/sawdust combination was weaker or poorly packed we noticed much more buckling, while the foam was stable for the most part given its very low weight. Future constructions could benefit from digital structural analyses to clearly identify weight/strength ratios of different materials in different locations of the structure and to remove redundant members while adding ones where needed most. The implications for such architectural systems are vast, however; as the tube skin can accommodate for any desired material injection, dependant on one’s exact design, site, and structural needs.