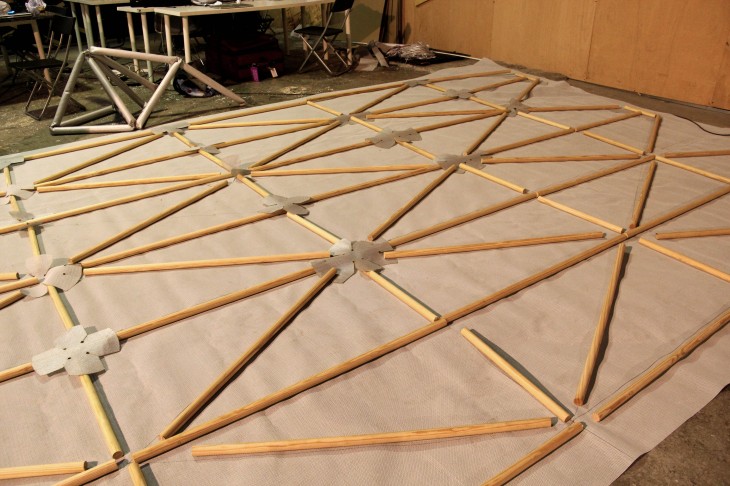

A collapsible modular tensile structure that allows you to set up a seating and a shelter wherever you want, a rolling cocoon in which you can rest in several different positions before rolling away again and again, a green parametric pavilion formed by a performance-specific components capable to build up a structure out of sawdust and fabric, a foldable fabric shelter able to unfold and possibly stand up as a minimum origami structure….

All of these experimentation have been shown on the 22nd of May at the final presentations of the seminar “lightweight structures 1:1″ at IAAC.

The aim of the seminar, led by Silvia Brandi and Rodrigo Rubio, with the collaboration of Pepe Ballestero (ETSAM Prototipolab) and Maria Kupstova, was to build four lightweight structures using structural fabric, within the format of an intensive workshop.

For the development of the project the course counted on the partnership of Serge Ferrari company, which provided the high-performance fabric Stamisol FT 371-3048 and Stamisol FT 381-3128.

The seminar has been developed in two sessions of three days each: in the first one four groups have been formed around four research topics: tensegrity structures, tensile structures, pure tension structures and fibrous structures.

During the first phase each group developed a project proposal and went trough some material testing and prototyping. During the second phase the construction of the four pavilions has been carried out in IAAC.

At the final presentation the students presented their projects to the jury board, formed by Ramon Sastre, tensile structure expert by ETSAV-UPC, Carmelo Zappulla, IAAC Faculty and principal of External Reference, Areti Markopoulou, MAA Director, together with the IAAC Alumni and Staff Mathilde Marengo, Dori Sadan and Moe Beagle.