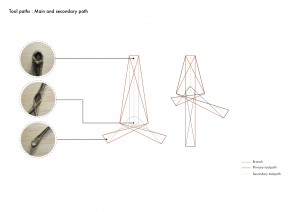

With the focus within the design community towards green technology; there has been an emergence of bio- composites. Some make the statement that bio-composites work better than standard composites. Hemp posses a great fiber that should be utilized within bio-composites. The branches of hemp, with their hollow core, work exceptionally well at retaining resin thus creating a more solid material. Focusing towards the innovative properties involving bio-composites we have discovered our thesis. How can we manipulate the fiber properties of hemp through branching?

With a relatively short growth cycle of 120 days and the ability to be planted densely at a rate of 3 to 5 hundred plants per square meter hemp has great potential to become a cash crop. Hemp is a plant that has a wide range of uses. In fact, “cannabis sativa” means “useful” (sativa) “hemp” (cannabis). The plant is very tall; ranging in height from 1.8 to 4.8 meters with majority of each hemp plant being comprised of a thin stalk, with no natural branches, and relatively few leaves. How can we train a plant that wants to grow straight up with no branches?

While many crops have been biologically manipulated over the years to increase yields, hemp has stayed fairly old-fashioned in its growth. Plants have been forced in many different directions; whether this is by a specific type of farming practice or going so far as to genetically modify the organism itself. More and more today we see a shift back towards natural practices. While some contemporary farming practices still rely heavily upon GMOs or heavy handed farming techniques, we see a niche market to utilize natural practices and augment the growing environment to manipulate the plant’s growth in a specific way.

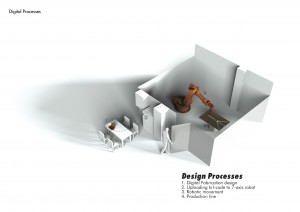

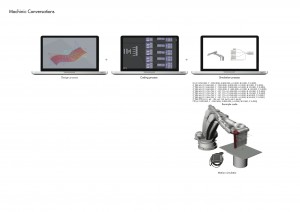

We will work towards hacking the plant through branching. Increasing the yield of the hollow branches that have good fiber development these fibers could be utilized in bio-composites, a burgeoning new territory of design. A major competitor to hemp is the flax plant which has a shorter height, thus creating a simpler fiber to extract, by hacking the hemp we hope to create a better plant. While some contemporary farming practices still rely heavily upon GMOs or heavy handed farming techniques, we see a niche market to utilize natural practices and augment the growing environment to manipulate the plant’s growth in a specific way. Utilization of new technologies such as the 7-axis robot and other tooling procedures will become ingrained in the study. Monitoring our project from the beginning through the end will help us define a detailed development of fabrication protocols.

booklet:

http://issuu.com/vince42/docs/branch_bio-fabrication_protocols

Video :

https://vimeo.com/69259997

Research Website :

http://fabricationecologies.wix.com/hempdatabase

booklet:

http://issuu.com/vince42/docs/branch_bio-fabrication_protocols

Video :

https://vimeo.com/69259997

Research Website :

http://fabricationecologies.wix.com/hempdatabase