Automated ventilation systems are usually complex building features. Moving elements require motors that add cost, weight and energy consumption to the construction, while they are often significant in size, reducing the structure’s visual delicacy.

Smart materials are here to change this paradigm and open the path towards a new architecture.

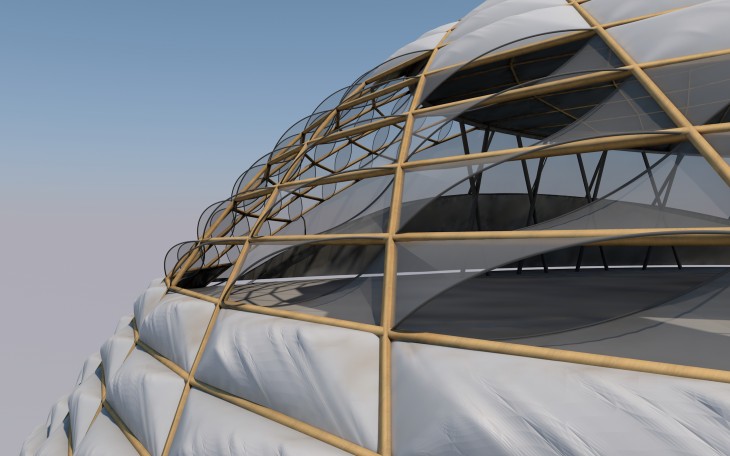

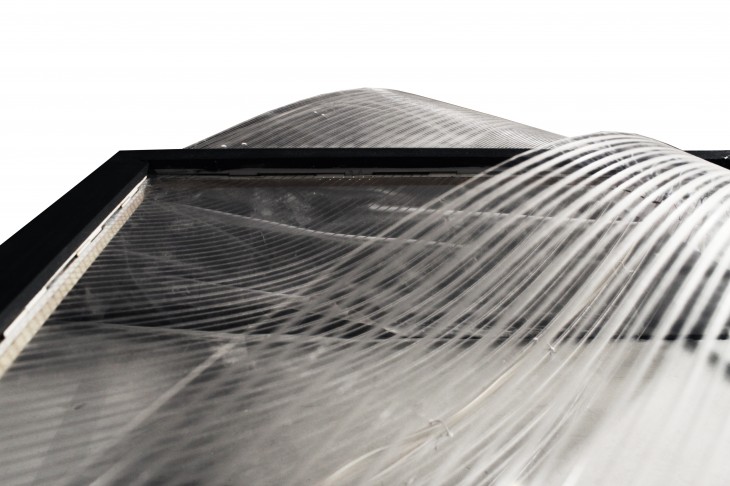

The breathing panel is a low cost, lightweight, durable and efficient modular ventilation panel. It uses a shape memory alloy wire to create an opening equal to 35% of the panel’s total area.

As technology advances, so does the needs of architecture augment. Building structures are becoming more and more dependent on machinery and, consequently, energy sources. The shift to a self-sufficient approach on architecture, comes with a reconsideration of conventional mechanics, used to provide, amongst others, temperature regulation, ventilation and shading. Kinetic systems are seen in architectural applications, more often nowadays, but they usually come with complicated mechanical supports.

New trends in architecture indicate new radical

paths for solving these problems. The effort is

focused on introducing more efficient, economic, ecologic and cost-effective solutions inspired by nature. Parallel to the investigation on mechanics, the study and creation of new materials is constantly ongoing. New, unexploited material properties are discovered or engineered, showing the shift of the path to a paradigm where construction materials display special new properties. These materials can exhibit behaviors that would need much more effort to achieve with conventional technology.

During the last two decades (1984-2004), world energy consumption has rapidly increased, along with all its frightening consequences. Primary energy consumption has grown about 49% and CO2 emissions about 43% during these years.

In Europe, buildings are responsible for about 37% of the global energy consumption. In Spain this percentage is about 23%. Around half of this percentage comes from the use of HVAC systems (Heating, Ventilation and Air conditioning systems). Predictions indicate an important growth in energy consumption for building‘s air conditioning in Europe for the next 15 years, of around 50%. Maintenance costs of HVAC systems are also a considerable effect on the country expenses.

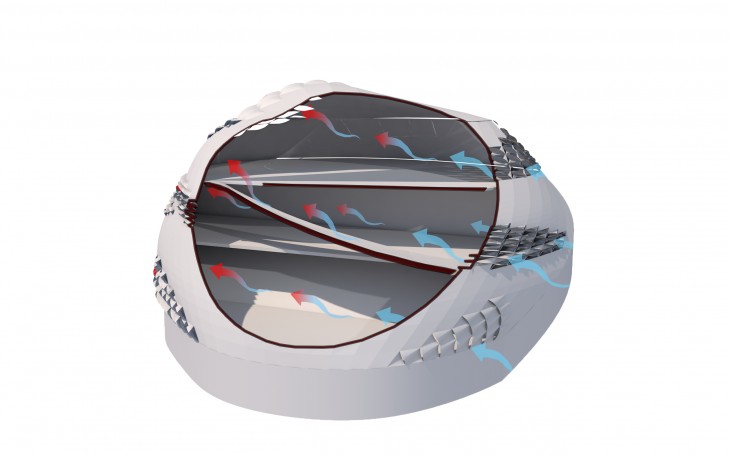

In a metaphor where buildings are living organisms, ventilation and air conditioning systems are a life support struggling to keep a sick entity alive. Our research focuses on the development of a system that helps a building breath on its own, according to the environmental conditions and the inhabitant‘s needs.

Ventilation and shading systems are usually complex building features. Moving elements require motors that add cost, weight and energy consumption to the construction, while they are often significant in size, reducing the structure’s visual delicacy. Ventilation and shading, though, had always been an important issue when it comes to sustainability, therefore, research on smart materials and intelligent constructions applications in this field is essential. On the very first stages of our research we realised the potential of intelligent kinetic mechanisms for these types of applications.

Frame and panel structures in architecture are generally considered fixed and rigid, but flexible ones can yield kinetic properties. This would make a structure able to “respond” to external stimuli, thus becoming “intelligent”.

Our project illustrates our approach on these matters. By researching and exploring various “smart” materials, and eventually choosing one, we combined the use of advanced digital tools and fabrication machinery to design and fabricate a functional prototype that can be used as an alternative to conventional ventilation systems.

FIRST APPORIACH

The initial exploration field of the research was the bending of frame structures. This emerged from our experimentation with threads. While testing thread patterns on thin wooden frames, we realized that the collective force of multiple threads is enough to bend the frame. This lead us to the idea of a structure consisting of bending frames.

Trying to implement a behavior to the system, we were called to find a material that would actuate a responsive system. So, the research continued with the exploration of thread materials that could be used as bending agents. In parallel, we investigated on an appropriate material of the frame as well as suitable fill material that would make the panel suitable for architectural application.

ACTIVE PANEL

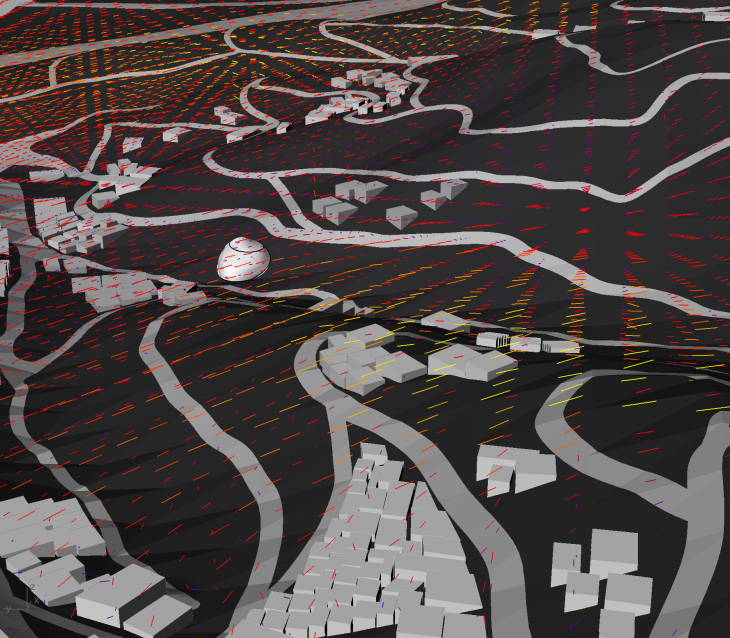

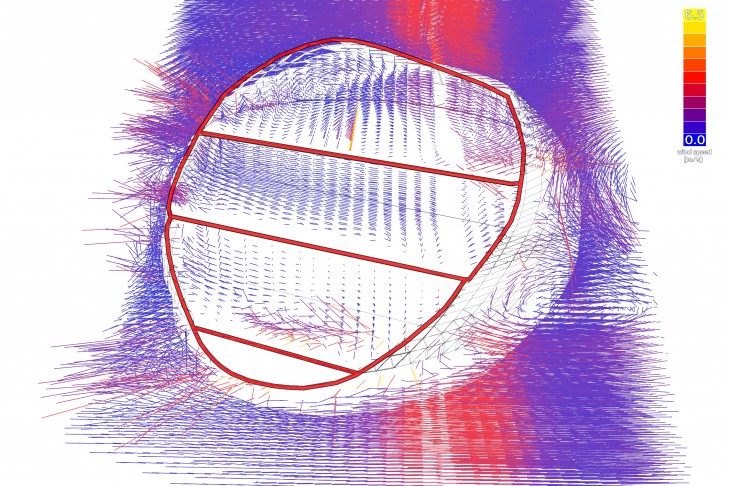

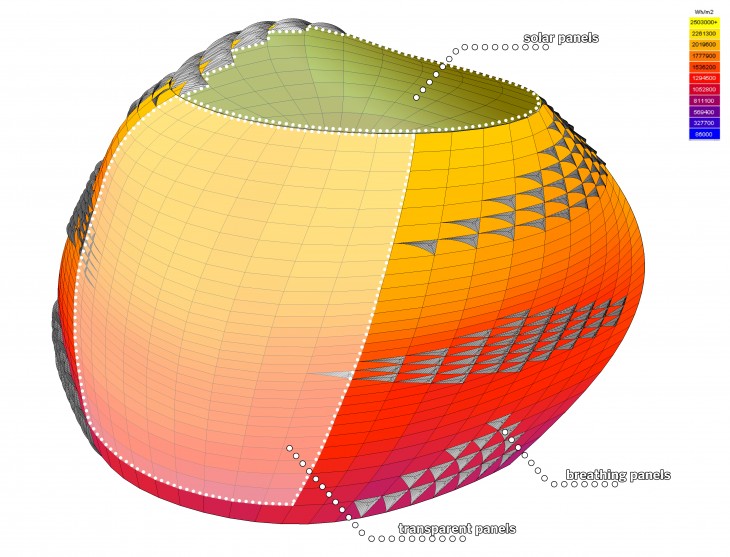

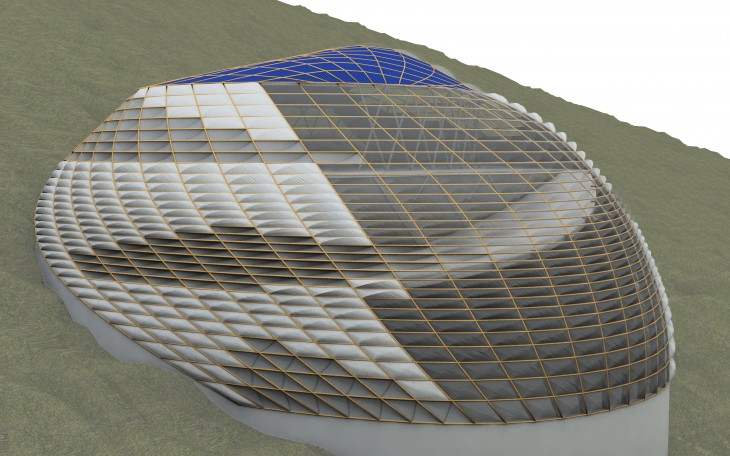

The final phase of the project focuses on active ventilation panel components. Panels consisting of a rigid frame and a flexible fill material that bends to create openings. The panels are combined to form a ventilation system that can have an application on a roof or on a facade. The mechanism that provides the actuation is connected to a sensor system than can adjust the openings according to the enviromental conditions (tempeature, humidity, wind etc).

The research physical outcome consists of a prototype component that can be part of the overall skin structure. It provides basic protection from the external environmental conditions, while being able to offer openings on request. Important parameters taken into consideration is the size of the openings, the efficiency of the mechanism, as well as the minimization of cost and energy consumption.

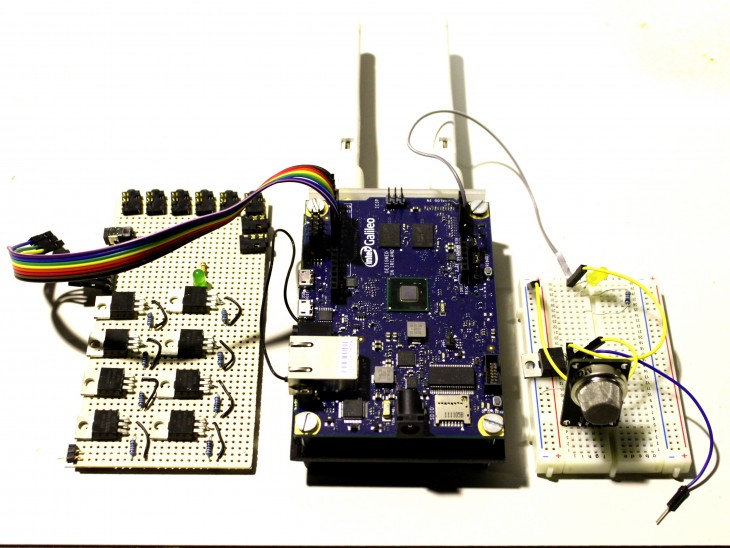

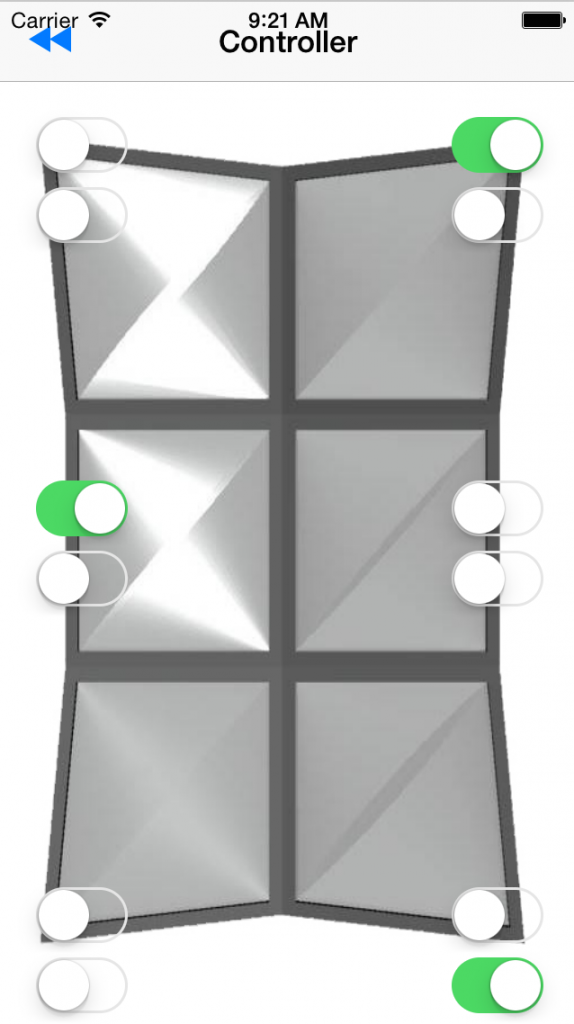

In order to facilitate on-demand actuation, we developed an application running on iOS and Mac OS.

Built in Objective C, the application allows the user to remotely control the panels’ state and receive real-time data via udp protocol on a local network.

The sensor data collected concern values of light, temperature, humidity and air quality. Notification of extreme value detections can also be received.

Our research gave us the oportunity to experiment using a responsive material. By studying its behavior as well as its advantages and limitations we drew conclusion on how it could be used in architecture. After a thorough multi-directional experimentation phase, we focused on an application that is of essential architectural meaning.

The use of muscle wire as an actuator of an opening-closing ventilation panel mechanism demonstrated the capacity of “smart materials” to serve as real-scale building elements.

A system like that has a series of advantages:

First, it consists of modular lightweight components. There are no motors or mechanisms involved, which means that the structure is significantly lighter and visually delicate.

The actuating mechanism itself is more reliable than a conventional equivalent. Muscle wire does not rely on mechanical or electical parts. I relies on its own chemical composition. It is autonomous and can be actuated practically infinite times. Maintenance cost is therefor minimal.

The overall construction cost is also low. Less weight and absence of sophisticated mechanisms means easy, low cost construction and assembly.

Video Link:

Breathing Panel on Vimeo.