Manifest

Utilising an incorporative system, consisting of various inputs, can result in exceptional efficiency when attempting to generate an effective yield of a product.

Coupling the potential flexible functionality of an aeroponic growth system with the passive manipulation of heat movement creates an ideal environment for many varying cultivars.

To achieve the most efficient form of execution it is necessary to take similarities among the cultivars into account. Focusing on tomatoes, several varieties are similar in terms of maturation time, harvest time, disease resistance as well as plant growth preferences . Therefore the growth of several varieties makes sense.

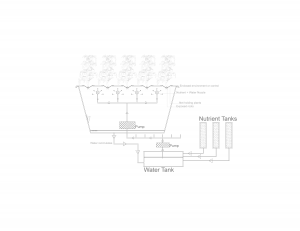

Once combining the tomatoes with the aeroponic system, numerous differences are instantly omitted. The germination and rooting periods of the plants, shrink down to less than a day. Most soil-based deterrents as well as plant-to-plant activity are eliminated, greatly decreasing infection and mortality rates.

The following step is to interconnect the aeroponic system with the passive growth proposal. Through undulating surfaces, which feature varying sizes of ‘hot pockets’, much like a series of ‘overlapping’ domes, the plants are subjected to the ideal conditions required. Being placed inside the ‘hot pockets’, the plants are essentially enclosed in a controlled heat environment, with the heating effect altering itself according to the stage of development the plants are experiencing.

Since heat rises, it is possible to capture and control it using the rippling effect created by the overlapping entities or ‘hot pockets’. The effects of the sun and mist sprayed by the aeroponic system proliferate heat gains and losses, therefore causing a constantly changing interior atmosphere. Through careful consideration of sun exposure measured on a grid of points laid on the site, it was possible interpret the information to form the surface of interlocking ‘hot pockets’, manipulating the heat to ‘travel’ around the created structure.

Through this passively encouraged movement, heat levels among the pockets change and adjust, correlating with the plants needs.

Large prototype model. This informed our proposal through the studying of the various occurrences on the model itself. Anti-spaces, 3 dimensional arrangements, unit composition as whole as well as individual panel varieties provided great insight into the behaviour of our chosen material when set up in such a manner.

Our initial experimentation of the material ‘Polymethyl Methacrylate’ revealed the effects of our chosen environmental parameter for the project, heat. We were able to study the material, subjecting it to varying degrees of heat and varying times of exposure, hence being able to confirm predicted effects and extrapolate unforeseen behaviours.

Further study of the component under heat stresses. Angles of deformation depend on heat intensity and time of exposure.

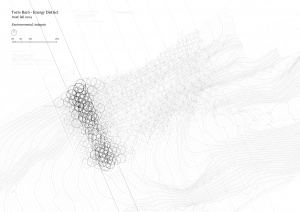

Through utilising Ecotect analysis software we were able to extract information for heating incidents, specifically for our site but also for the general surroundings. Understanding these values as geometries, in this case circles, we were able to in effect ‘plan’ the proposals positioning on site. The greater the diameter of a circle, the greater the energy signature from the suns heat/light in that specific spot.

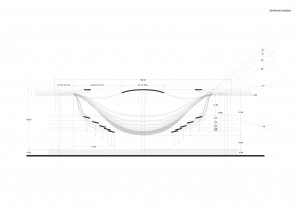

Transferring the earlier information extracted from the circles, we began interpreting these figures as height differentials, giving us vertical lines of varying heights (all in the context of the site). In this case the higher the lines goes, the smaller the amount of energy that spot receives. Included in these representations are the number of hours of sun exposure each originating point receives. By simply connecting the highest most point on each of the individual lines, longitudinally as well as latitudinally, we are informed of the extents and general geometry of our proposal as well as the defining heat/energy parameters for plant growth in the specified areas. With this technique we are able to delineate the scope of the proposal.

Looking at Philippe Rahms theories on ‘Interior Atmospheres’, specifically convectional currents, we attempted to transfer the idea into our proposed design. The idea for us was to passively move heat around the dome-like chambers, which house the plants, through roof geometry. As heat is generated on the interior through the suns incident rays falling on the transparent ETFE surface of each of the domes, the air inside is heated, changing the composition of the air, which in turn creates interior currents. These currents push heated air around the domes. Through the use of electrochromic devices (smart glass; changes opacity to let less/more light through depending on light sensors) mounted between the ETFE surfaces it is possible to control the degree of heating inflicted by the sun, and therefore it is also possible to control the convectional air currents inside, providing the ideal temperatures for every plant in every ‘dome’.

Tomato research on similar tomato varieties we wish to grow. These have been selected due to their similarities in many defining areas (maturation time, germination time, sun exposure preferences etc.).

Set up of the individual domes. Plants sit on a ‘canopy’ in the ideal temperature range. These are able to be harvested from underneath by human collectors. The aeroponic system is set up to capture the excess water and recirculate it for greater efficiency. The electrochromic devices mounted in between the ETFE panels are shaped according to the rhombus design of the individual components, creating a seamless ‘covering’ of the subjects, and therefore enabling complete control of the heating effects of the sun.

Arranging of the individual ‘domes’ according to groundcover.

Connections among the interior, ‘sealed’, spaces.

Growth units inside each of the ‘domes’.

Main plan, including representation of potential paths people may take to either simply pass by the proposal, harvest a crop or observe.

Final model in 1:50 scale.

Final Render