Smart materials are highly engineered materials that sense environmental events, process that sensory information, and act on the environment. These materials are able to “remember” configurations and can conform to them when given a specific stimuli (electric, stress, pH, etc).

Architects have conceptually been trying to fit smart materials into their normative practice alongside conventional building materials. Smart materials, however, represent a radical departure from the more normative building materials. Whereas standard building materials are static in that they are intended to withstand building forces, smart materials are dynamic in that they behave in response to energy fields. The advent of smart materials now enables the design of direct and discrete environments for the body.

The emergence of smart materials facilitates biomimicry, which is a field of study and imitation of nature’s methods and design processes. Mimicking nature’s mechanisms offers enormous potential for the improvement of our lives and the tools we use. Electroactive polymers (EAPs), and in particular, dielectric electroactive polymers, are one of the emerging technologies enabling biomimetics. Polymers that can be stimulated to change shape or size have been known for many years.

The activation mechanisms of such polymers include electrical, chemical, pneumatic, optical and magnetic. Electrical excitation is one of the most attractive stimulators able to produce elastic deformation in polymers.

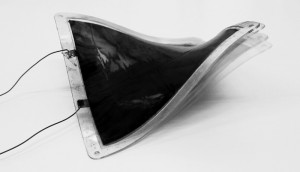

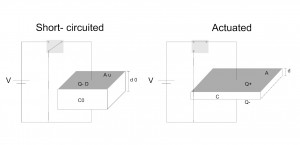

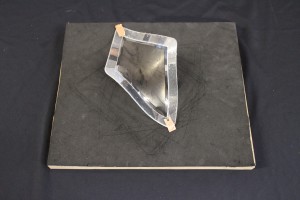

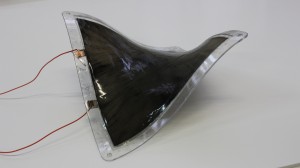

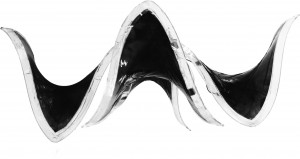

A dielectric EAP actuator acts as a capacitor, where a thin elastomer film is sandwiched between two compliant electrodes. When a high DC voltage (kV) is applied to the electrodes, the arising electrostatic pressure squeezes the elastomer film in thickness and thus the film expands in planar directions. When the voltage is switched off, the elastic film returns to its original shape in an organic fashion. So far the composite has been used as electrostatic transducers, prosthetics, micro-air vehicles, braille displays, flat-panel loud-speakers.

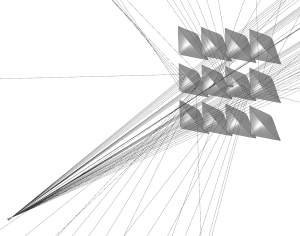

Within a two months period, this project aimed to experiment with the material, and propose a suitable application for it through a top-down approach. Finally settling down to the idea of using it as a tool to adjust the acoustic performance of building interiors by using sound as an input to manipulate the space within, creating an enhanced indoor environmental quality.

Sound manipulation

When the two electrodes are polarized, they squeeze on the elastomer, hence increasing the surface area.

- EPA fabricaton:

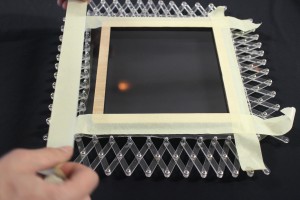

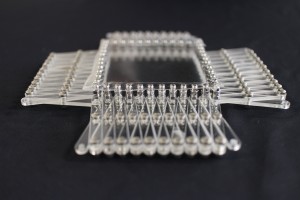

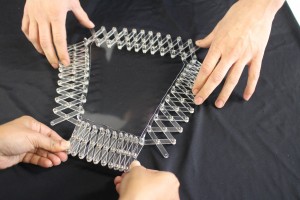

Scissor mechanism stretcher

VHB Elastomer

Cut to desired size

Place on elastomer

Stretch size uniformly

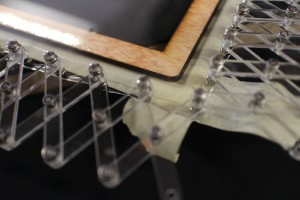

Laser cut frames

Reinforce edges of the frames with masking tape

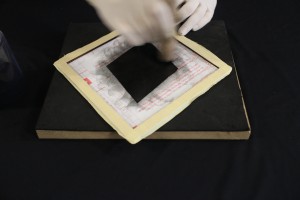

Apply Carbon Black powder

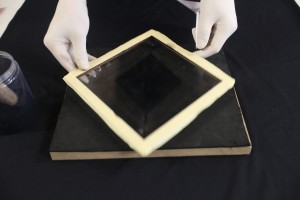

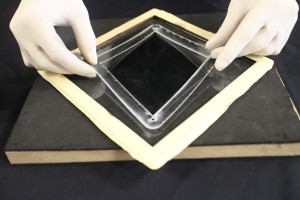

Add polycarbonate frame

Apply silicone evenly and consistently. The silicone layer will make the elastomer more durable and safe. However, the silicone affects the deformation and the actuation of the modules.

Cut the elastomer around the outside border of the polycarbonate frame frame.

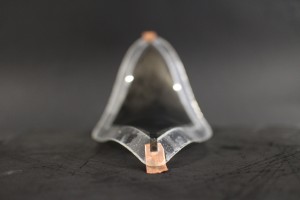

Add copper electrodes