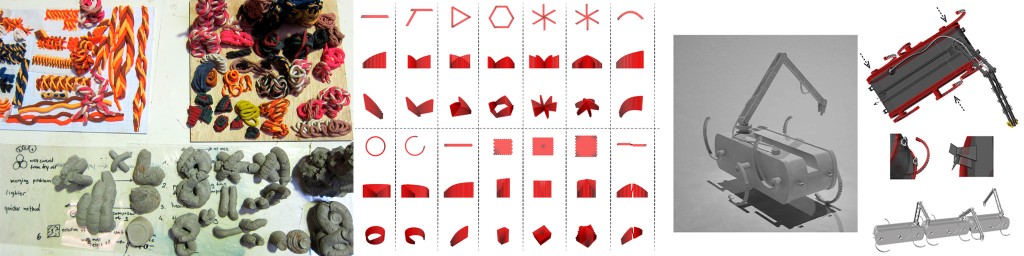

Flexi Moulds, aims at developing a universal building constructions system which is based on multi materials wherein the primary material acts as a mould or scaffold while the secondary enables in constructing the desired structure.

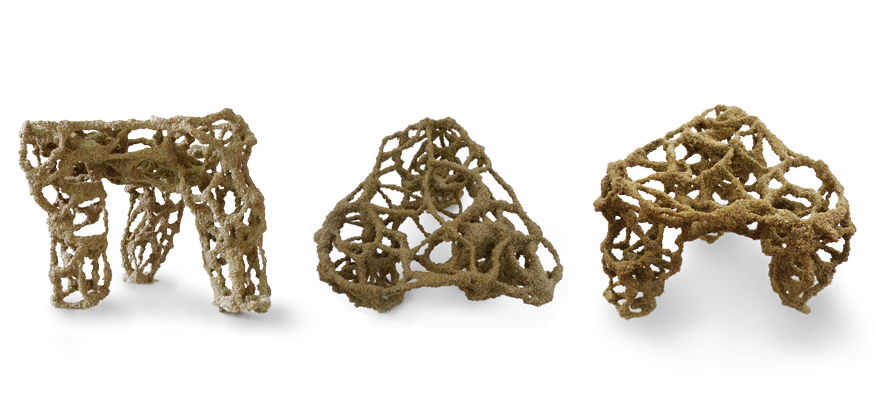

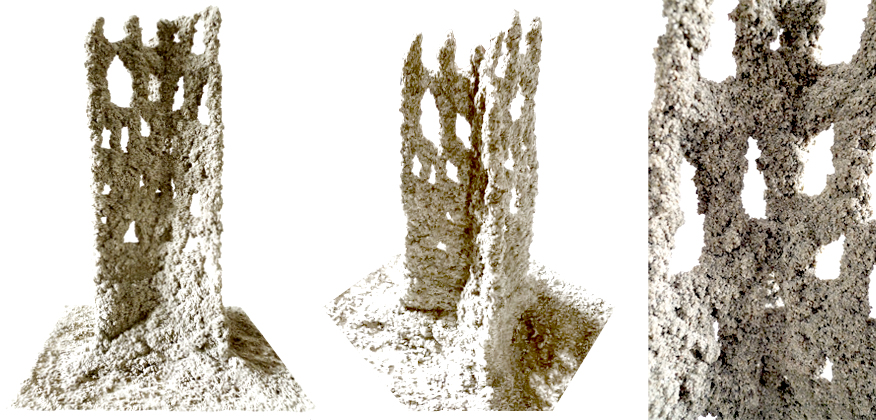

Our research deals with the most abundantly available natural granular material i.e SAND, which when subjected to load is best in taking heavy compression load. Apart from having the advantage of being reused, the material flow when choreographed and programmed as desired, produces complex harmonious forms and patterns. By following these patterns, we could create structures both organic and symmetric, multi layered as well as multi module structures.

A detail study of behaviour of single sand pile and behavioural change of the same pile due to interaction with multiple piles, has been our focus to generate algorithm or complex network by simulating the granules both at micro and macro level. The algorithms are generated by treating the surface of pile as contours and are used to define the trajectory of mortar flow. Also, the perimeter of piles are used to defines the curvatures while the interactive points are used to generate the main structural support system. Thus the resultant structure is designed to take compression load at all scales.

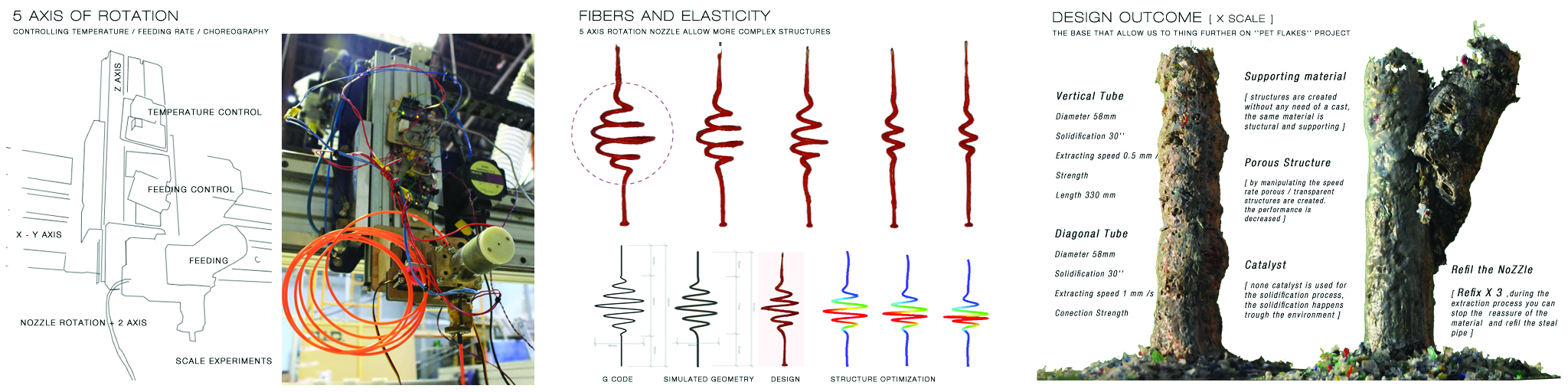

Fleximoulds is also working towards developing a insitu construction system, wherein the support material could be easily moulded and later on removed easily once the main structure is set without any technical complications. The system also aims at developing a feedback system on the real time conditions of deposition of primary material, so that any changes in the resultant structure could be incorporated before execution. The same is also subjected to optimization in terms of material usage and structural stability.