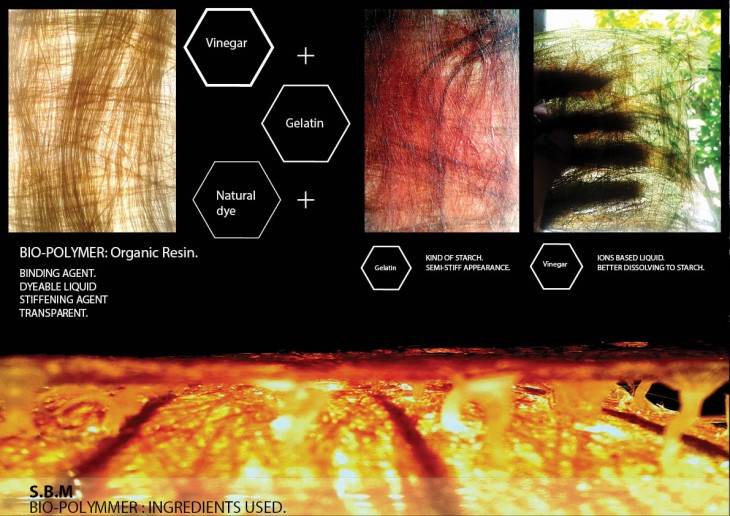

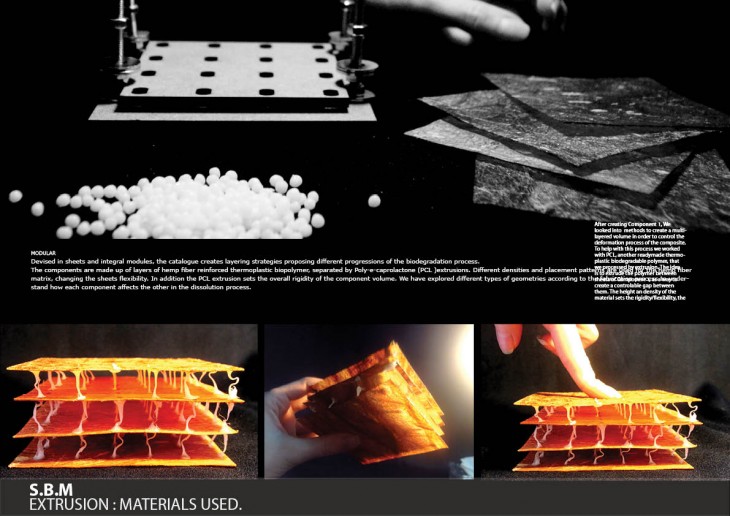

The research explores production methods and material behaviours in plastic biodegradable systems. It investigates DIY biomaterial production and passive reconfiguration processes to create components for a dissolving architecture. Our IBB catalogue presents a range of lightweight biobricks suited for low impact ephemeral structures undergoing passive distortion scenarios, until organic blending with the site is reached

The research explores production methods and material behaviours in plastic biodegradable systems. It investigates DIY biomaterial production and passive reconfiguration processes to create components for a dissolving architecture. Our IBB catalogue presents a range of lightweight biobricks suited for low impact ephemeral structures undergoing passive distortion scenarios, until organic blending with the site is reached

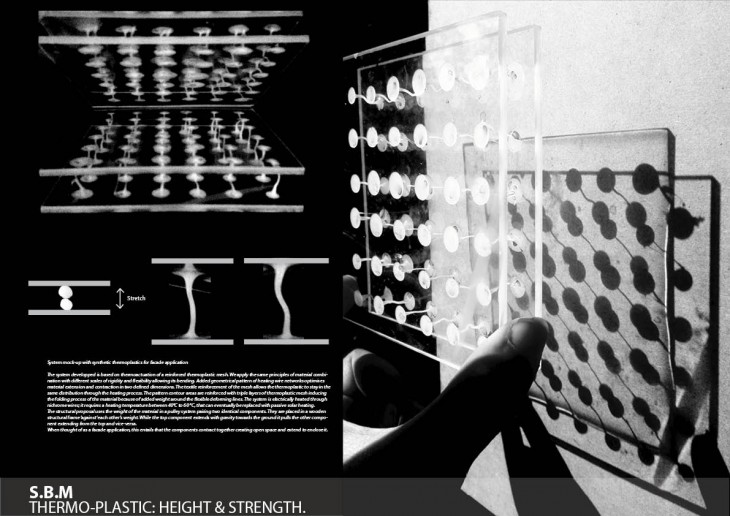

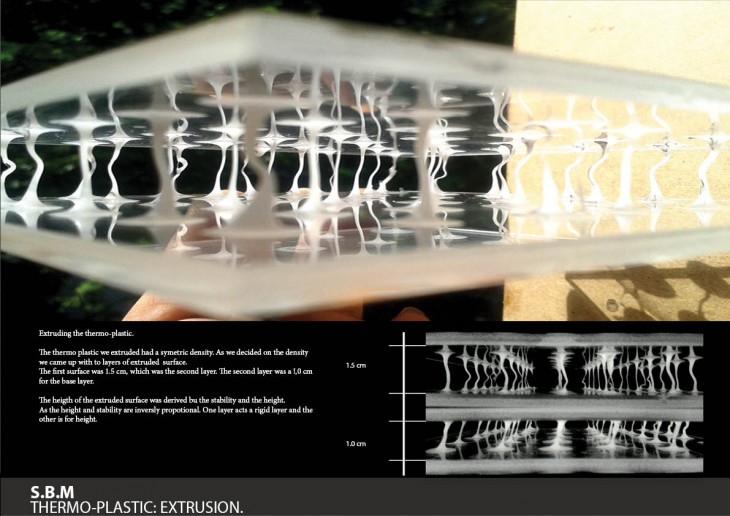

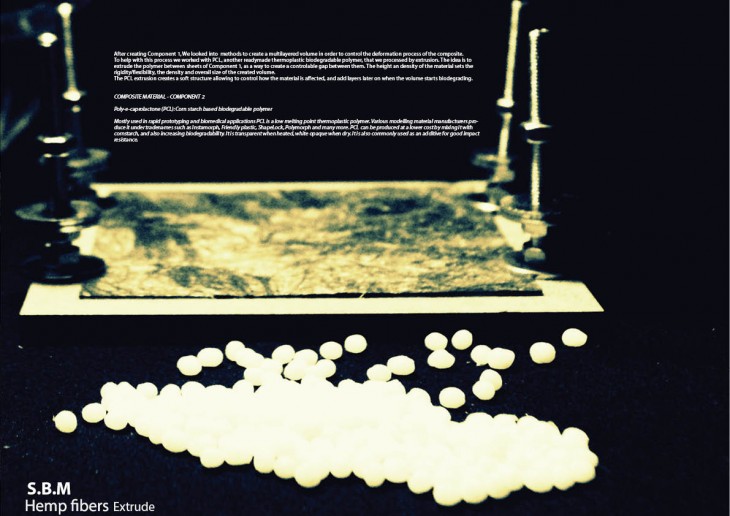

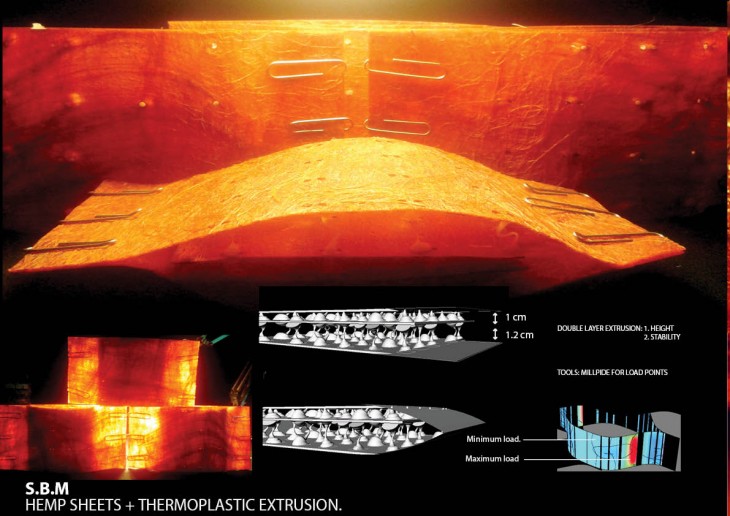

Bio-logical – In the first phase of the research we looked into material plasticity for programmable use. As part of a Life inspired and regenerative concept, we studied production feasability of biopolymers and their thermoplastic performance in passive+ and artificial systems. In the continuation of the project we further developped the idea of a malleable system, focusing on passive biodegradation with rainwater, or induced degradation by artificial moistening.

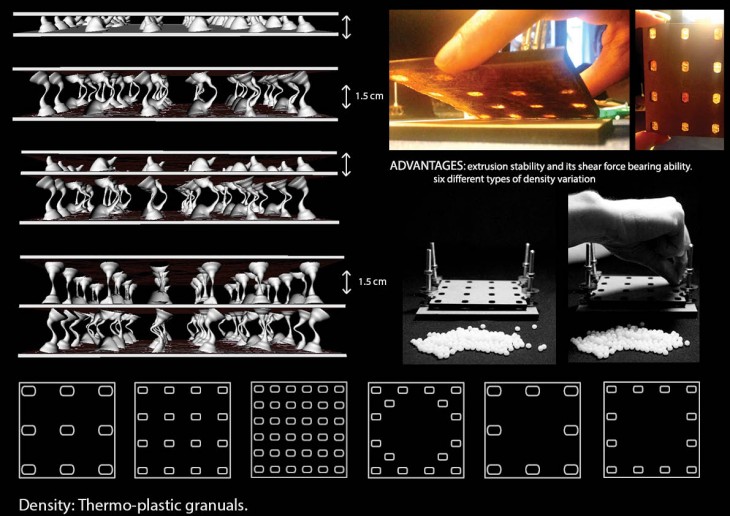

Thermo- plastic.

Modable plastic.

This plastic becomes moldable at a tempreture (90 c.)., and solidifies

at room tempreture.

Reheating it: Can be used agian.

Bio-degradable plastic.

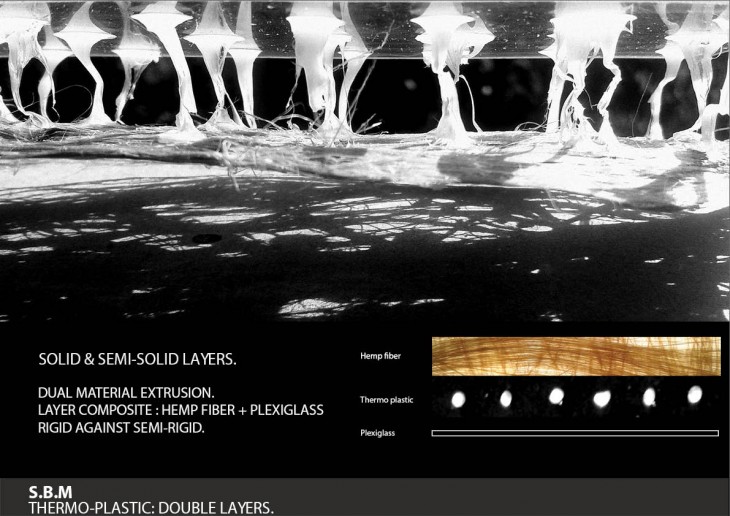

This plastic bonds with certain plastics when hot. like.. ABS, acrylic,

polyester, PVC(ex: tubing) and viny (3 ring binder), parchment paper.

This plastic does not bond well with: wood products and most metals.

plastics like: nylon, polypropylene, silicon and teflon.

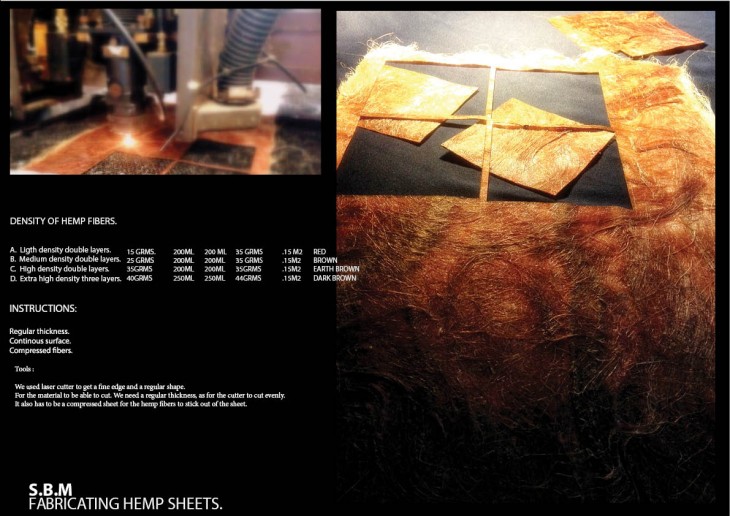

Hemp Fiber

Natural Fiber

Hemp is stronger than any other natural fiber. the properties

includes abrasion resistance and tensile strength.

It has a longer life span.

It also holds its shape, streching less. Hemp is used in upholstery,

demountable panels, acoustic paneling or as wallcovering from

stretching out or becoming distorted with use.

Hemp has light reflective quality. It possesses excellent soil-release

properties because it sheds a microscopic layer. This eliminates

soiling and exposes a fresh surface, retaining its sleek shine

everytime it is washed.

Good absorbant properties: It feels cooler in summer yet during winter

because of air trapped in the fiber is warmed by the body, making it warm.

Hemp has high resistance to ultraviolet light.