Energy is at the centre of contemporary urban landscape development like water has been an important factor for ancient cities establishment and expansion. In pre-industrial times rivers and lakes have been strongly influencing the morphogenesis of cities however presently contemporary energy infrastructures are instead often segregated from the city itself, hidden in places, not considered relevant to an urban life. This form of segregation inherited from modernity (zoning) appears across scales and regimes from the urban to the material, as we can observe from the classic juxtaposition of arrays of solar photovoltaic cells over landscapes as well roofs and facades.

The studio aims at the subverting this paradigm of segregation by envisioning novel bio-technological prototypes whose morphology, materiality and esthetic novelty are emergent qualities of specific flows of energy and information.

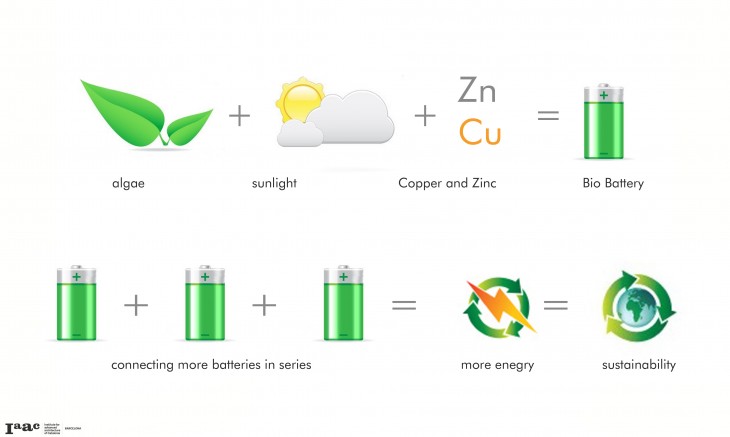

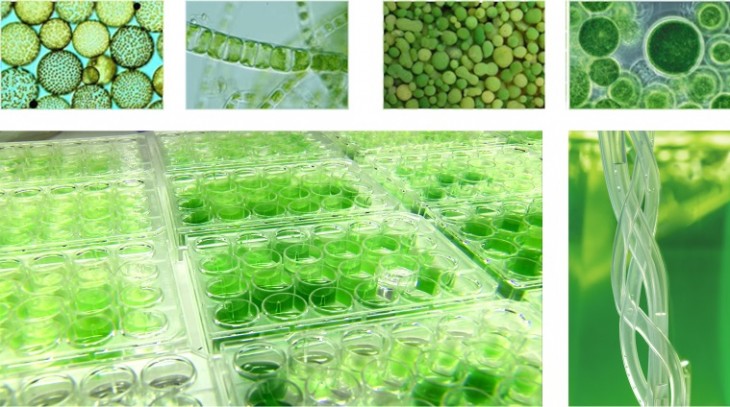

Biophotovoltaic (BPV) devices are biological solar cells that generate electricity from the photosynthetic activity of living microorganisms such as algae. When light falls on the algae, a series of reactions take place which split water into protons (hydrogen ions, H+), electrons and oxygen. These are vital ingredients for transforming carbon dioxide and other inorganic materials into things like carbohydrates and proteins which allow the algae to grow. Biophotovoltaic devices exploit this charge separation to generate electrical energy.

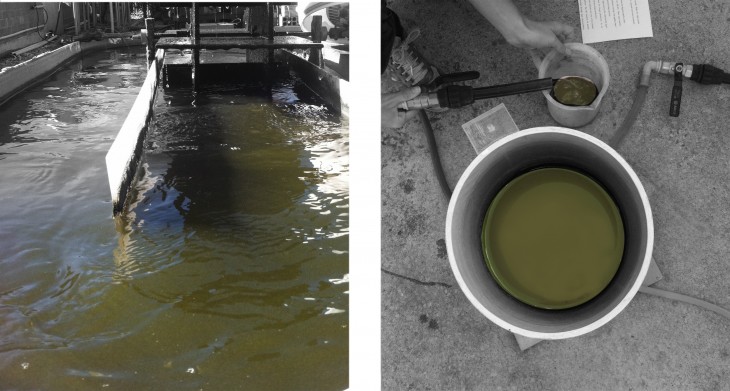

Collecting biomass

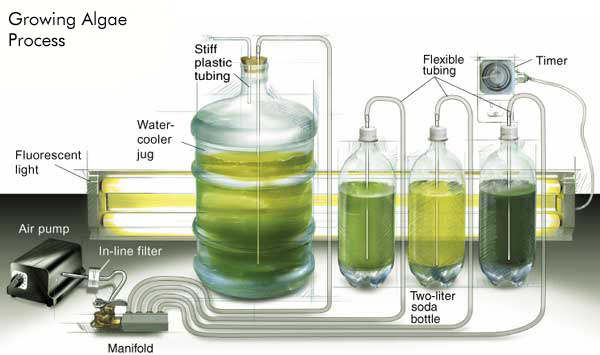

As first research studio, the algae where collected from sweet water directly from the site and placed in a transparent container. Within indirect light, water temperature between 18°-22°C, input of extra nutrition, absorption of CO2 and turbulence of the water algae have optimal environment to grow.

Experiments – measuring efficiency of algae

In our research we have been doing several experiments in order to find out what is the best way to construct an algae photo cell.

Experiment 1

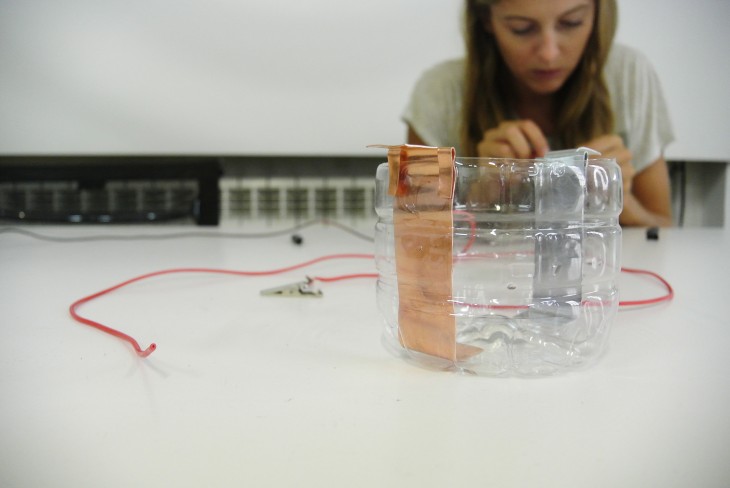

In container we placed plates of zinc and copper, one at each side. In this way between the two plates, put electronically in a serie, an electronic field will be created. Algae have been mixed in water and distributed equally in containers, resulting in small voltage.

Experiment 2

In a single container we inserted and connected in serie greater amount of copper and zinc plates to test if it will enhance the interchange of the electrons between copper and zinc and if it improves the result from experiment 1 -it turned out that the result did not change.

Experiment 3

Algae has been distributed following in 4, 8, 10, 12 and finally 20 containers, following the previous connection of zink and copper plates – the greater amount of cells resulted in higher voltage.

4 cells are enough to power 1 LED light (3V)

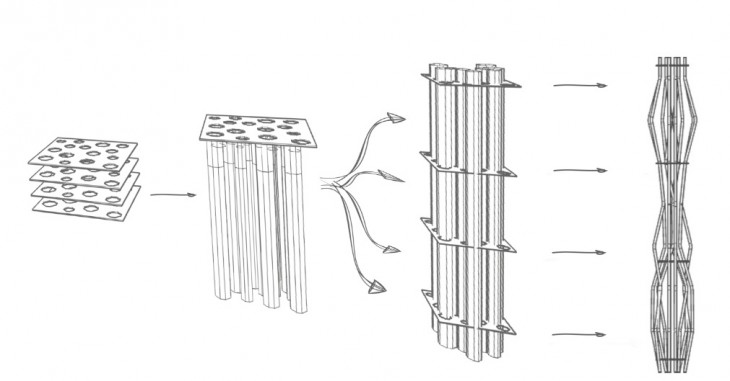

First prototype

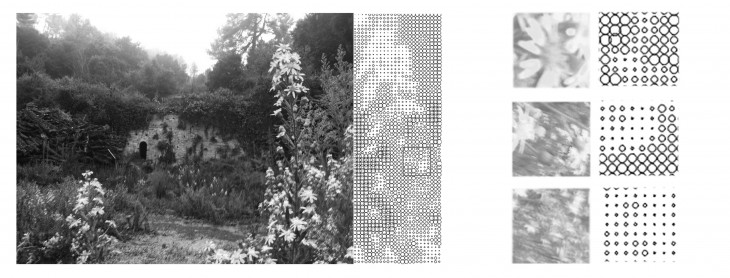

From pattern that was generated from the forest of Valldaura we arrived with the design of our prototype made of transparent plexiglass in order to accommodate for maximum sunlight exposure on algae.

Set of 4 plexiglass sheets with holes and and engravings were cut using a laser cutter. First sheet only contains holes that will create cell walls as well as the holes to place LED lights, second sheet we use to increase the depth of cell by placing holes in the same axes.

Third sheet contains engravings for the wire paths and placement of zinc (Zn) and copper (Cu) plates and finally fourth sheet only serves as a plate that will create bottom for the cells.

Assembling process of the first prototype

Second prototype

For the second prototype we decided to use plexiglass plate as a holding structure where extruded cells have been attached and connected in series using Zinc and Copper plates.

Assembling process of the second prototype

Only one horizontal element was used but with the help of supporting elements, and the algae cells have been extruded in order to avoid evaporation of the water when exposed to high temperatures.

Of particular interest are the equal level of algae cells placement that gives an opportunity for maximum exposure of light and allowance for turbulence of the water to be created when ever the tubes are moved.

The process of extruding cells (placing them in the tubes) resulted in default of distributed weight, which had to be compromised by additional supporting structure elements. Following the process we came to conclusion that in future prototypes we need to implement structural elements within the material used for the pipes

Third prototype

Third prototype is constructed using a more advanced method, in this case we have 4 horizontal elements that serve as a structural pieces- holding the cells together and only one supporting element in the middle.  Each horizontal element consist of a pattern resulted from the research we have done in the field regular tessellations.

Each horizontal element consist of a pattern resulted from the research we have done in the field regular tessellations.

Regular tessellations

Regular tessellations of the plane by two or more convex regular polygons such that the same polygons in the same order surround each polygon vertex are called semi regular tessellations, or sometimes Archimedean tessellations.

In the plane, there are eight such tessellations, illustrated above (Ghyka 1977, pp. 76-78; Williams 1979, pp. 37-41; Steinhaus 1999, pp. 78-82; Wells 1991, pp. 226-227). Williams (1979, pp. 37-41) also illustrates the dual tessellations of the semi regular tessellations. The dual tessellation of the tessellation of squares and equilateral triangles is called the Cairo tessellation (Williams 1979, p. 38; Wells 1991, p. 23).

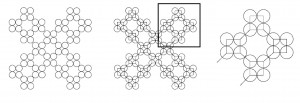

Truncated square tiling circle packing

Truncated square tiling circle packing

The truncated square tiling can be used as a circle packing, placing equal diameter circles at the center of every point. Every circle is in contact with 3 other circles in the packing (kissing number).

Geometry of the joining piece

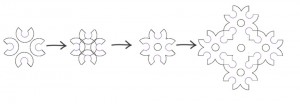

The process of creating a plexiglass horizontal plates using earlier investigated circle packaging design, from 4 separated elements to the one that connects 20 algae cells by the level.

In order to make the structure more stable we used cells material as a building element to create a structure with only one supporting element that does not participate in the energy production.

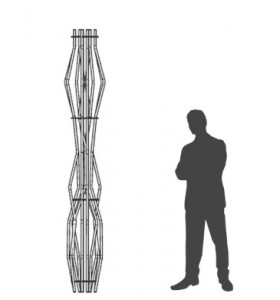

One column

Each of the connections arrived from our experimentation of circle packaging, this way we created free standing structure, with equal distribution of material weight, using only one supporting element in the middle.

In order to create more organic shape we interlocked the tubes in between each other on different vertical and horizontal axes.

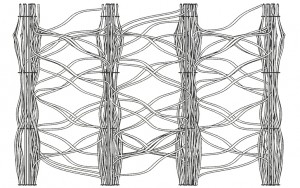

Interconnecting of the columns

Interconnecting of the columns

By interconnecting columns we are creating a “life” corridor. We want to design a special space dedicated to this new energy solutions. The experience that each individual has while passing through this installation, should have an effect on a perception of how we can be more involved in the process of energy production and increase our awareness level of ecological possibilities that are easily available.

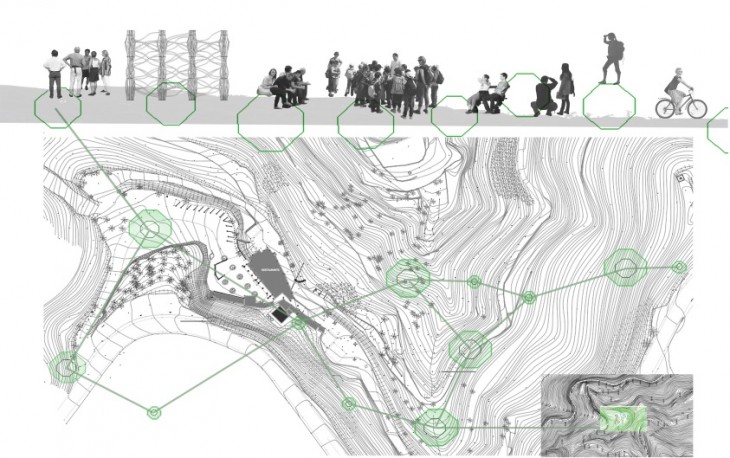

Site proposal- forest of Valldaura

Site proposal