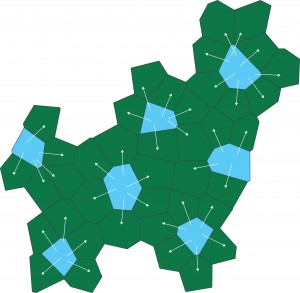

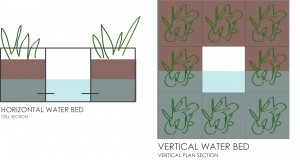

The goal of the installation to be done is to do a surface of bio-photovoltaic panels that may be applied to any surface and produce both electricity and food (mainly herbs). In previous prototypes the surfaces were tessellated by using a Voronoi tessellation. This would allow us to efficiently irrigate the plants by keeping the best ratio water cell to plant cell being irrigated as shown in the following diagram.

This was the idea that drove further prototypes to be tessellated by Voronoi with subsequent modification in terms of shape, height variation, tiling, etc. As these prototypes where developed though, the impracticality of this irrigation system in vertical surfaces became evident. The system works well by creating a water bed all with the same level around the water cell yet, when placed vertical, the level of this water bed turned and so neither all plant cells where receiving water nor did it keep the proper water level for those it did.

Hence, this irrigation system was discarded and substituted by a drip irrigation system powered by a submergible water pump and a tube running along the cells to water them. By substituting the water system, the Voronoi tessellation of the surface was rendered useless since there is no other aspect of it that is beneficial for the system. This freed the design consideration and opened up new possibilities for the prototype. The first being the tessellation method, the surface could be subdivided in ways that are more beneficial to the plants themselves. Second, the rigidity of the system, the surface doesn’t need to have fixed stiff walls to contain the water. Finally, the new irrigation system allows for free flowing tubes to extend through a surface which allows surface flexibility rather than achieving the height difference by making the walls higher or lower. The idea then is to transfer a generic surface with photovoltaic panels into any surface, independent of the shape.

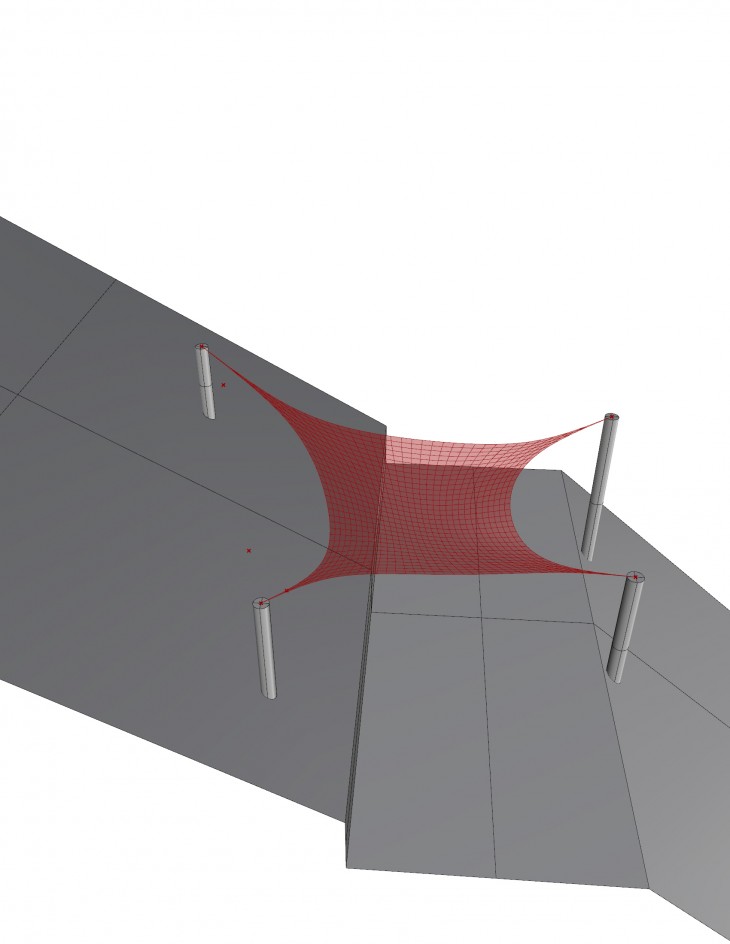

To find the surface to apply the generic surface to, the first step was to find the location in Valldaura. The site that was selected contains four trees to develop a cable surface in between them with which the path that goes undernearth will be covered.

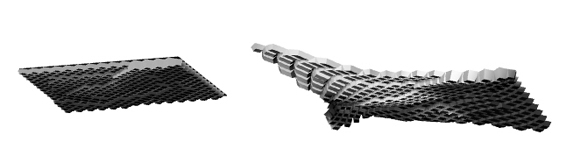

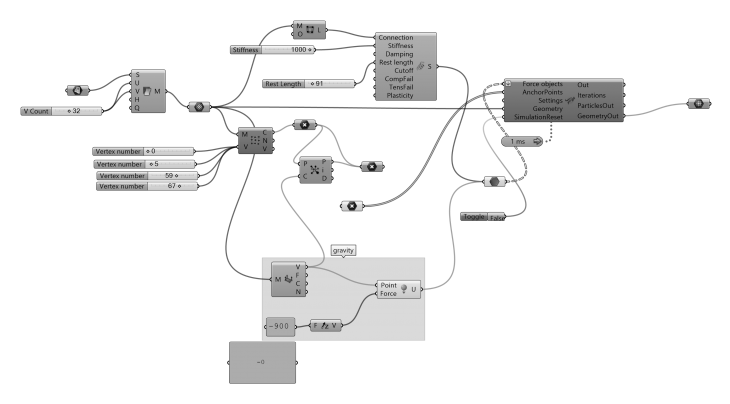

After this, the site was recreated in Rhino and four cables connected in between the four trees. A mesh is created in between this cables and a grasshopper/kangaroo scrip is run to simulate the gravity affecting it.

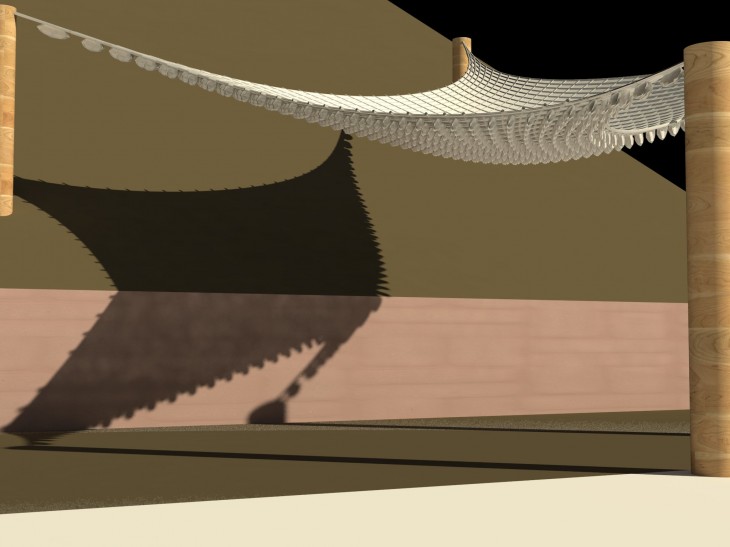

Once the mesh is simulated, it is tesellated in a inner polygon subdivision which gave us inner cells in between the “cables” of the mesh. This inner cells are the ones to become the photovoltaic panels. After having this, through a weaverbird/grasshopper definition, the cells where inserted.

The fabrication process will be done by milling the mold of the individual cells and casting it in pigmented rubber due to its flexibility and water resistance. It will be suspended by tension steel cables and raised into position.