Designed as an entirely self contained, self automated & self powered external shading device, the WindBlind detects the outdoor climate and blocks or allows solar radiation to maintain a constantly comfortable indoor environment.

The WindBlind is the product of the exploration of electricity generation and application.

A final product with multiple energy saving prospects, the WindBlind has been subject to thorough research & intense design development.

Initial Concept

The idea of harvesting energy from the wind is not new. There is evidently mass commercialisation of wind energy, mainly in the form of rotary wind turbines. Therefore the intent was not to create a new wind turbine, but rather to understand the natural energy, & any possible social & sustainable benefits which could be attained by adapting wind energy to various scales.

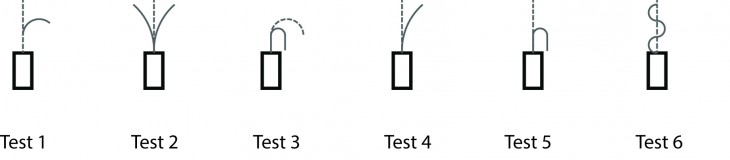

The concept of the wind belt was developed, refined, & revitalised. The wind belt was an attractive option to us due to it’s simplicity. The system required an input of slow speed wind to create aeroelastic flutter – a movement which would cause a magnet to osolate through a copper coil. The lack of mechanical or moving parts in the harvesting of energy has many fundamental benefits – mainly high durability & low maintenance.

The social implications of the technology were addressed, & the resultant design outcome was a self powered, automated, isolated shading device, whose application covered a range of functions such as shading for glazing & outdoor public and private spaces.

Electricity generation

Copper Coils & Magnets

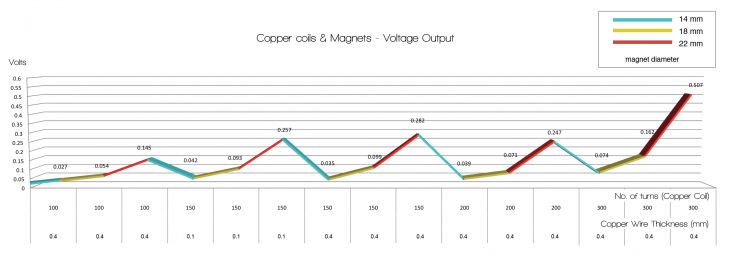

Understanding the energy production of copper coils & magnets was a thorough part of our research. We fabricated many copper coils, with various combinations of turns, thickness in copper and using dual or single coils in one unit.

The relationship between the copper coil turns and the size of the magnets used was a direct indicator to the energy produced.

Thorough research of the efficiency of various copper coil & magnet combinations and piezo electric technology was conducted.

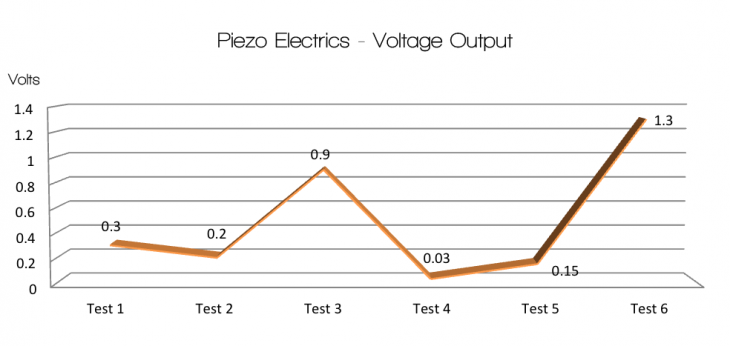

After several weeks of research and extensive testing, it was decided to use Piezo electric technology. The energy production is much greater (around 5 times higher per unit) than copper coils & magnets.

Piezo Electric Technology

The total cost of each Piezo was roughly equivalent to that of each copper coil and magnet unit. However, as indicated in the above graphs, the Piezo Electric Technology has a far more substantial energy production compared to that of the copper coils and magnets. Taking into consideration the weight, it was an obvious transition from copper coils and magnets (with a very high weight per unit) compared to that of the Piezo’s, whose weight was almost negligible.

Design Development

A number of designs were explored throughout the 3 month period, ranging from hand-held devices and belts hanging from trees to

outdoor furniture.

A major recuring theme, due to the low energy production of individual units, was to create a product comprised of multiple belts, having multiple piezo’s in parrallel.

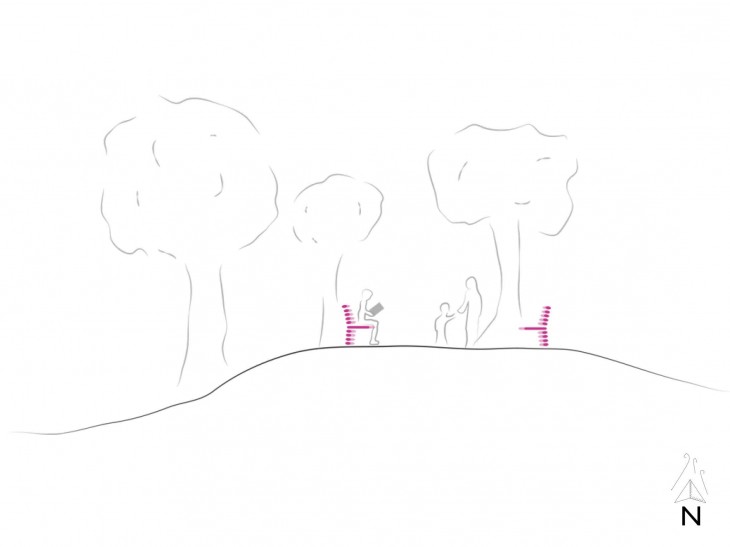

Wind belt technology could be incorporated into furniture – the structure of a bench would support wind belts between structural components, generating electricity for charging phones or lighting at night.

Hand-held, individual units were explored. Light-weight units would could be transported by hand, and could be taken camping to charge lights or phones/UHF’s.

Also developed at this stage of the design process was the “hanging belt” (in the centre of the image). This concept would would swing freely from a tree, and could be installed throughout forests.

An early idea developed was to infill a window from with multiple wind belts – an concept which could double as a shading device.

The above concepts had a number of problems to overcome, and were essential in our design process for understanding the problems that our product faced.

Firstly, individual units were too limited in their energy production. A system comprising of multiple units was essential for any significant output.

The second problem addressed was the disunified approach originally taken to the design. The structure, wind belt, and energy producing technology was all significantly seperated. This theme was continued through our design until late in the semester, when we developed the first wind blind – finding a design which could incorporate all of these systems into one unified product.

Early in the design process, we explored other methods of generating electricity from wind energy. The obvious system uses a dynamo in a rotary mechanism. We experimented with a helix form, which allowed a very lightweight object to have a large surface area constantly exposed to wind.

Early in the design process, we explored other methods of generating electricity from wind energy. The obvious system uses a dynamo in a rotary mechanism. We experimented with a helix form, which allowed a very lightweight object to have a large surface area constantly exposed to wind.

This design faced limitations in its inability to change direction with the wind, as well as its limited application to the site.

Prototyping

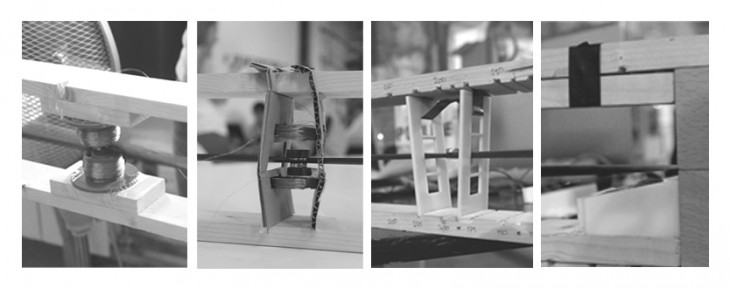

#1 The first model was to develop a small scale wind turbine that generated electricity using the aeroelastic flutter and induction copper coils. The intial prototype allowed us to test and explore the application of aeroelastic flutter, and the energy production associated with this method.

#1 The first model was to develop a small scale wind turbine that generated electricity using the aeroelastic flutter and induction copper coils. The intial prototype allowed us to test and explore the application of aeroelastic flutter, and the energy production associated with this method.

#2 The second prototype was an evolution of the first prototype, using multiple belts in a stacking system to increase the voltage output. It also worked with copper coils and magnets.

This prototype was developed mainly with the aim of testing voltage output from various copper coil and magnet combinations, as well as our first testing of Piezo Electric Technology. These tests were all combined in the one prototype.

#3 The third prototype constructed was to allow us to test a new design. The concept was based on the original theory of aeroelastic flutter, but used the Piezo Electric Technology in place of the copper coils & magnets, due to cost, weight and time of manufacture disadvantages caused by the copper coils & magnets. As well as being able to optimise the materials, we were also able to test the Arduino and electrical components, as well as optimized location and movement of the Piezo’s.

#3 The third prototype constructed was to allow us to test a new design. The concept was based on the original theory of aeroelastic flutter, but used the Piezo Electric Technology in place of the copper coils & magnets, due to cost, weight and time of manufacture disadvantages caused by the copper coils & magnets. As well as being able to optimise the materials, we were also able to test the Arduino and electrical components, as well as optimized location and movement of the Piezo’s.

The new concept was designed to infill a window at Valldaura, and was intended to be highly adaptable.

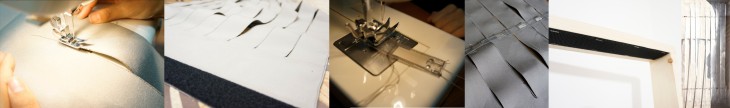

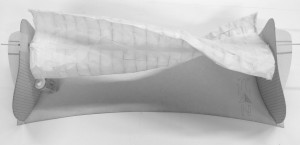

#4 The final prototype – a refinement of #3 – was fabricated to minimise the overall weight and components of the product. The system was simplified in many areas – such as combining the cable system (which makes all blinds move in unison) and the Piezo’s into one component.

#4 The final prototype – a refinement of #3 – was fabricated to minimise the overall weight and components of the product. The system was simplified in many areas – such as combining the cable system (which makes all blinds move in unison) and the Piezo’s into one component.

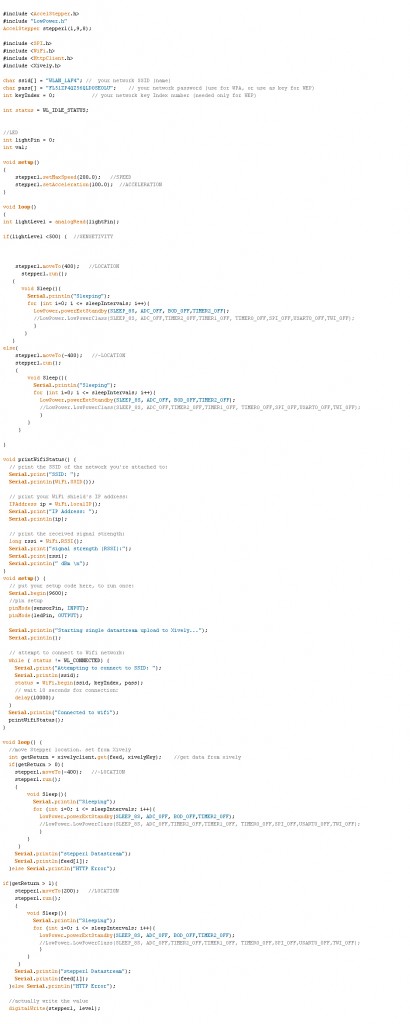

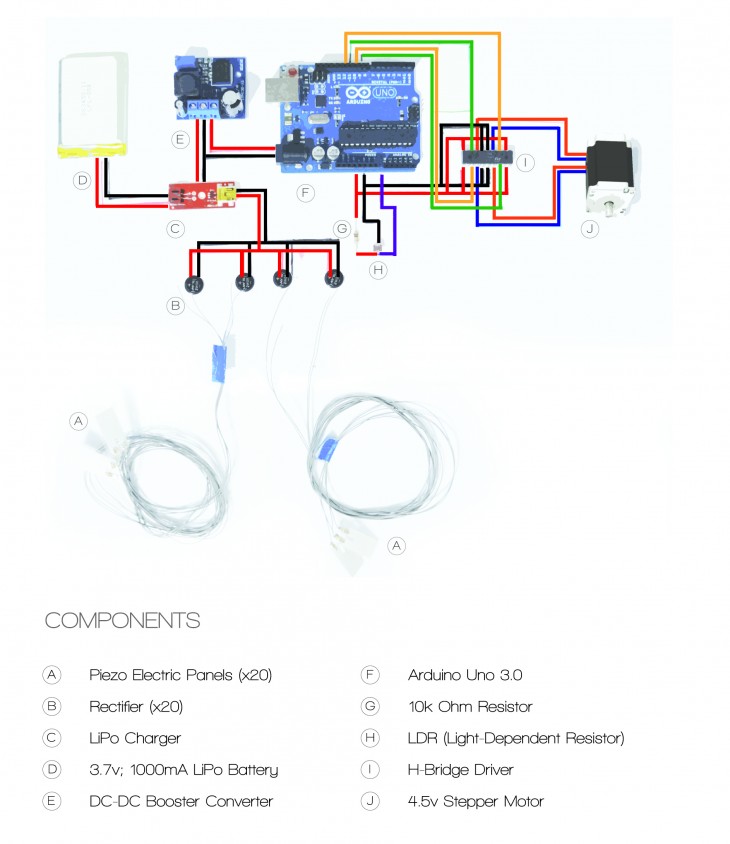

Arduino + Electrical Circuit

The WindBlind – A Product

The wind blind is designed to provide an automated, isolated, decentralized solar access control to any space.

Solar radiation and the access of sunlight to building interiors is a major factor in sustainable design. Although methods of controlling solar access are in abundance, these systems rely on human input, and therefore require direct monitoring from the building occupant.

The wind blind allows spaces to be sufficiently shaded or flooded with solar radiation based on the intensity of sunlight at any given time. Human interference and therefore the potential of human error is eliminated, ensuring precision and consistency.

Input & Output Processes

The Arduino is programmed to receive two inputs: one from the sun (light levels, read through a Light Sensor); and one from a remote control (SmartPhone).

In automated mode, the Arduino will take a light level reading. If the luminosity is below a pre-set level (adjustable for seasons), then this will trigger the output – for the Stepper Motor to change position – therefore opening the blinds. The Arduino will then sleep for 3 hours (to save battery and ensure that the blind is not opening and closing at every passing cloud). After 3 hours, a new light level reading will be taken, and the blind will open or close to compensate for any change in luminosity.

The Arduino has been programmed to receive a manual input – from a SmartPhone. This will overide both the sleep mode and the light level reading (in the case of the occupant wanting privacy, or more ventilation – for example).

Passive Design

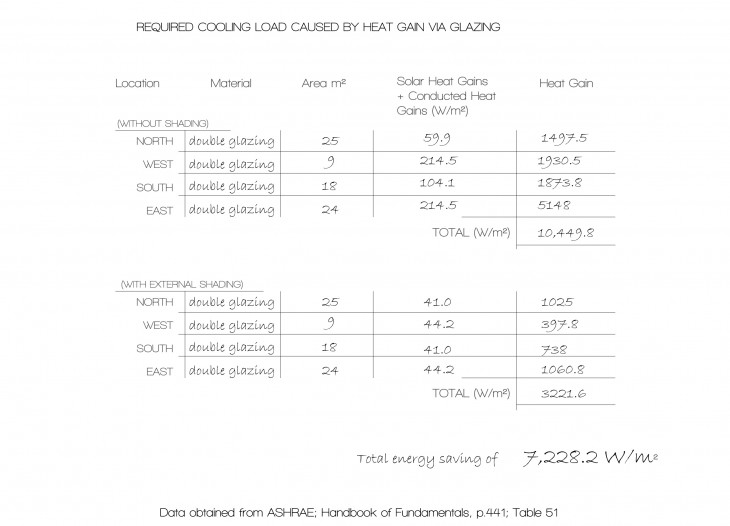

Solar Heat Gains play an important role in sustainable design. Solar radiation can be significantly advantageous to thermal comfort, but can also be hugely detrimental.

By allowing solar access to the internal thermal mass of the building, you create access to a free and comfortable heating source. However, if over-exposed, this can create huge discomfort, lasting for hours due to the time-lag of thermal mass materials (such as concrete, with a 9 hour time-lag in releasing its stored heat).

By ensuring consistent and efficient monitoring and access of solar radiation – accessability when needed but also shading as required – we can greatly reduce cooling and heating loads for the applicable building.

From the above example of cooling load reductions at Valldaura, we can see that there is a substantial benefit to having external shading on a building – approximately 3/4 of the required energy consumption to cool a building from solar heat gains is eliminated.

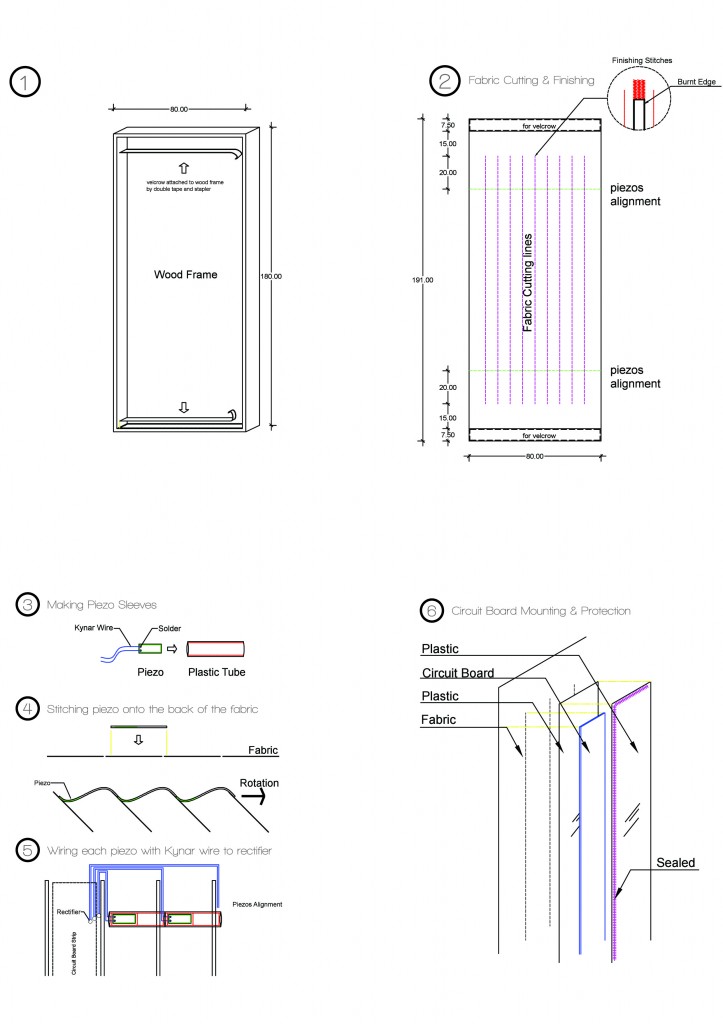

Fabrication of the final Prototype

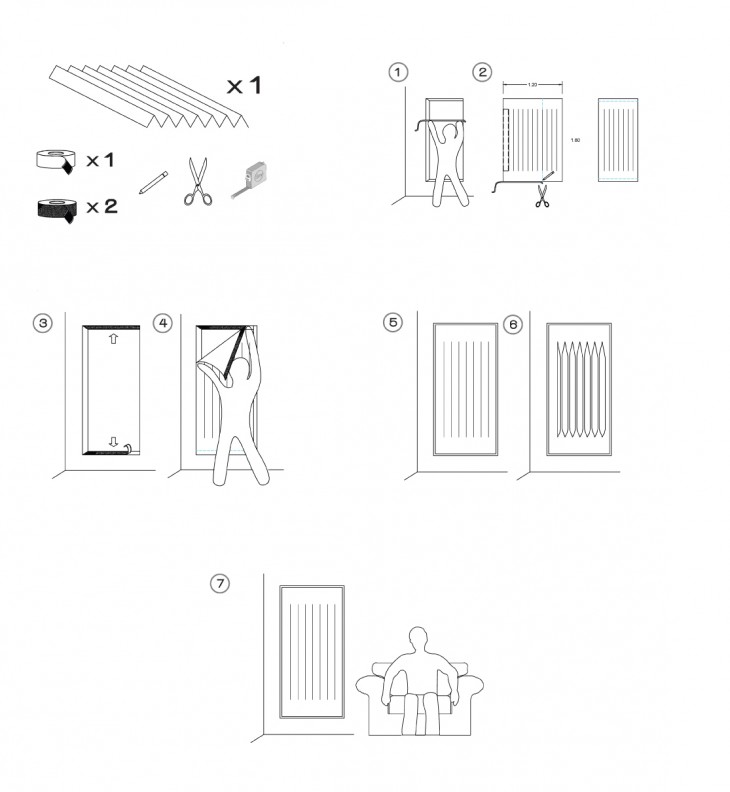

Installation Instructions

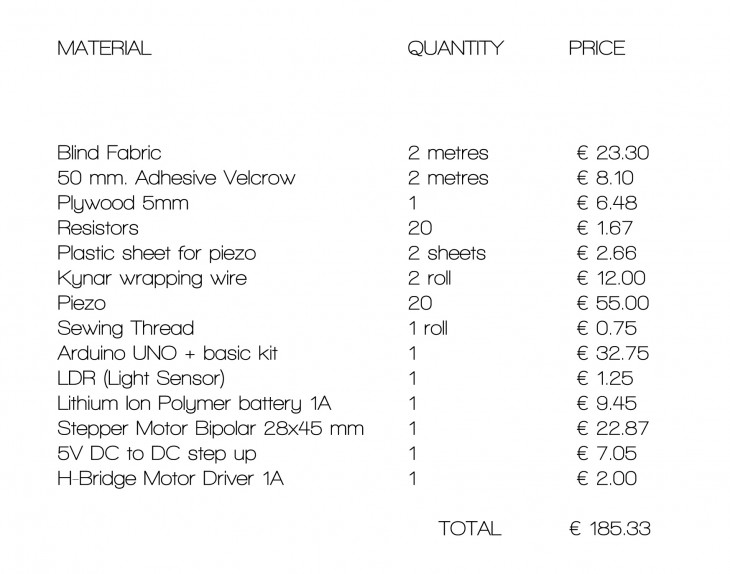

Cost

As displayed in this graph, the final prototype was relatively inexpensive to fabricate. The design process included consideration to the overall cost and weight of the materials used. It was important from the outset to reduce these features.

Weight

The overall weight of the unit was 2.4 Kilograms. This weight was mainly made up by the Stepper Motor (180 grams), the electronics & the mounting board.

Energy Production

Using 20 Piezo’s in Parrallel allowed us to average a 10 Volt Production with high wind speeds (>5 m/s), and a 2 Volt average during low wind speeds (>1 m/s; < 3 m/s). We were able to charge the 3.5 Volt Li-Po Battery in approximately 3 hours of average wind speeds at the Valldaura site (2 m/s).

Two Year Development

The major target for a two year development plan would be to create material made by laminated Lead Zirconate Titanite (Piezo electronic technology) in large sheets, allowing forms whose entire mass is dedicated to energy production.

Fifteen Year Development

The movement which is currently being controlled by a Light Sensor, Arduino and Stepper Motor (requiring the full energy produced by the system) will be replaced by using a Photoresponsive Polymer as the laminate material – as the material is exposed to sunlight, the polymers will change shape, forcing the material to bend to the designed form. This procecss will be reversed when there is no light.

The use of Photoresponsive Polymers will allow all of the harvested energy to be used for various outputs such as lighting public spaces and public charging bays (phones, computers, vehicles, etc.).

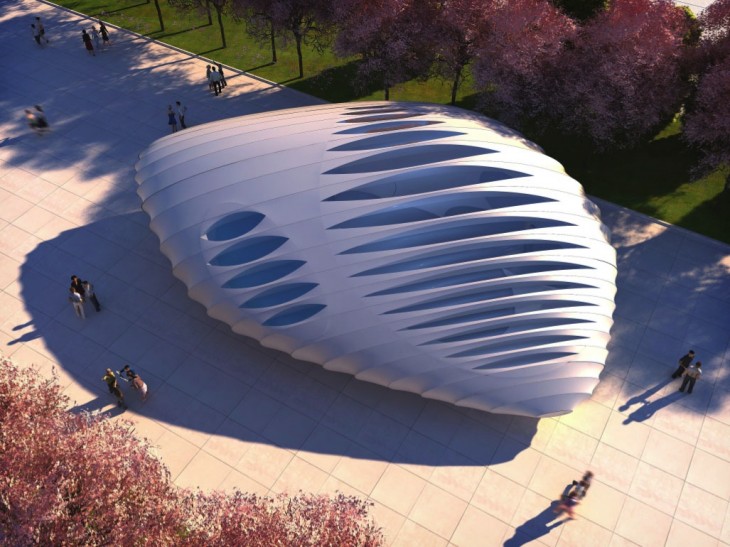

A static pavillion from ZHA. The WindBlind in 15 years could act as a second skin to buildings, allowing fully self-automated passive climate control. (source: www.bustler.net)

This pavilion from the South Korea SOMA Expedition was constructed in 2012. It uses a system inspired by biomimetic design. It’s limitation is the motor and mechanics required to change it’s form.

“One Ocean“ Thematic Pavilion EXPO 2012 : SOMA from Arch2O.com on Vimeo.