Back in the studio with a handful of components and a faint idea of the outcome by the end of the week. Exciting. This is the second week of Close to the Body. The same teams return to their prototypes and rethink, reiterate and redesign the wearable objects in order to make them sense and actuate and form some kind of communication among the wearable, the body and its surroundings.

Monday, March 11, Valldaura

After a brief morning introduction and short presentation by Eva Deckers from TU Eindhoven, we are in the taxis again, heading for Valldaura. At the site. In a windy and cold surroundings of the Collserola park we perform the original movements, wearing the prototypes for the new people to guess, comment and suggest the further steps. Trying the prototype enhancements, adding the objects of everyday-life, which we had been told to bring with us. Small bike LED’s, MP3 player, smartphones, flashlight, hair dryer, some more LED lights, all of these are being tested inside the wearables to see the immediate effect. After lunch we are given more time to identify the way of interactivity for our objects and find the means of presenting this way to other groups. Movement. Input. Sound. Output.

Our prototype should respond to a changing position of the body by making sound or vibration, suggesting the person to explore these sensations via movement. We find dry branches, which help us to communicate this idea in a simple way to the others. A person wearing the prototype moves randomly across the south terrace while the other person tries to follow and respond accordingly, changing the drumming patterns on the stiff felt surface of the prototype. Branches as drum sticks.

Tuesday, March 12, IaaC

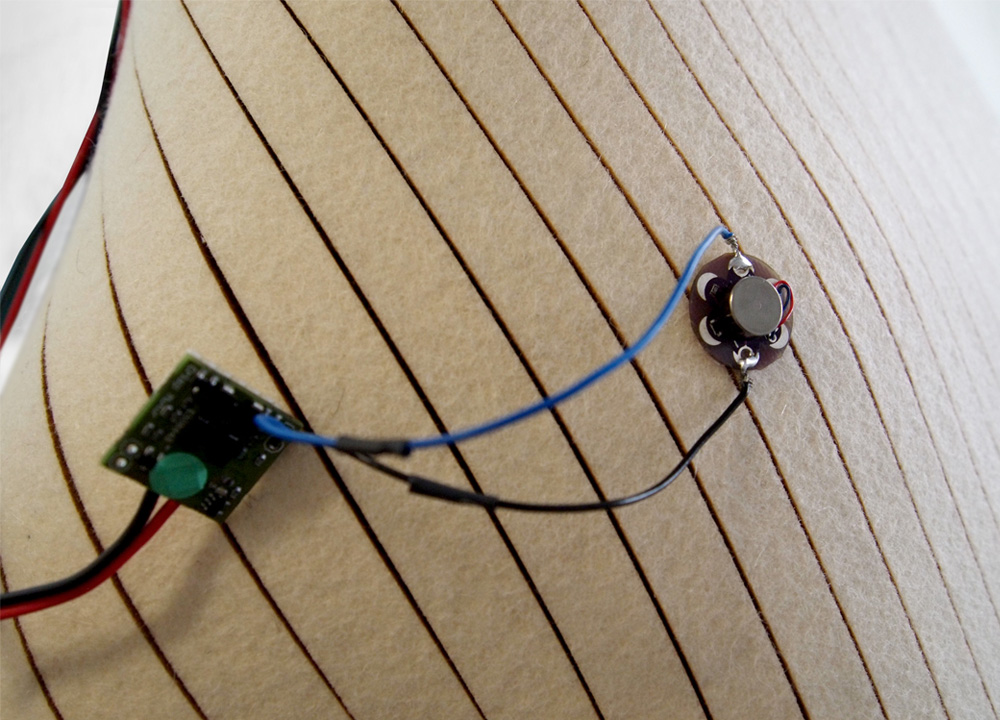

At IaaC again. Short presentation by Martijn ten Bhömer, who shows us some projects combining the textiles and electronics. We are introduced to the microcontroller shield prototypes, which had been developed at TU Eindhoven. Small boards, 30×30 millimeters, each with a microcontroller preprogrammed for a different input or output. LED lights, speakers, vibration motors, accelerometers. Tiny and easy to implement to the textile fabrics. We decide to test one of these boards programmed for small vibration motors, the ones from the LiliPad family. After building a simple circuit, using the board, vibration motor and 3,7V lithium polymer battery, we place the motor onto different parts of the felt prototype and try to understand how the material distributes the vibration and its effect on the body. The robust felt material with a high density of texture seems to spread the vibration waves quite well.

Time to control. Using the Arduino software, we check the program controlling the vibration motor, how it is defined and what are its time delays. Based on these findings we program three sketches which should explore how the motor effects the wearable and the body at the same time. High/Low, Fade and Pulse, these are the basic motor behaviors, which should help us to define the interaction between the garment and body.

Wednesday, March 13, ESDi

On an early morning train to Sabadell. ESDi today, with its wide corridors, spacious classrooms and student canteen. Sabadell Rambla again. The weather is cold and miserable. Smart textiles. Marina presents her Tumblr blog site. Textiles Now. A collection of various smart textile projects oscillating between high fashion and textile design. After that we are shown some samples integrating technology into the textiles. Various types of conductive thread, woven into the fabric, forming soft sensors, thermochromic ink, EL wires, conductive paint and fluorescent yarn.

Back to the projects. This time we work in a basement room. Close to the machines. Sewing, knitting and weaving will be needed. Today we test a new vibration motor, Cebek 6070, purchased the other day. 8000 rpm. Seems to work well, much stronger than the LiliPad motors. We should use this type of motor for the final prototype of this week. This motor has a tiny spinning tip so it needs to be in a protective case. We build an improvised one, using a small piece of transparent vinyl film.

We test the accelerometer sensor. LilliPad’s ADXL 335. Works fine. Doesn’t work with the preprogrammed microcontroller board though. These are designed either for an input or an output. We learn that it is not possible to control the sensor and motor with one board and a connection of more boards together would need a complicated serial communication protocol. Time to change the strategy. Finally, we decide to use the Arduino Fio for controlling 6 vibration motors and 1 accelerometer. We again test a quick prototype using a thinner type of synthetic felt. The vibration effect is not very intense and its various modes are almost imperceptible.

Thursday, March 14, IaaC

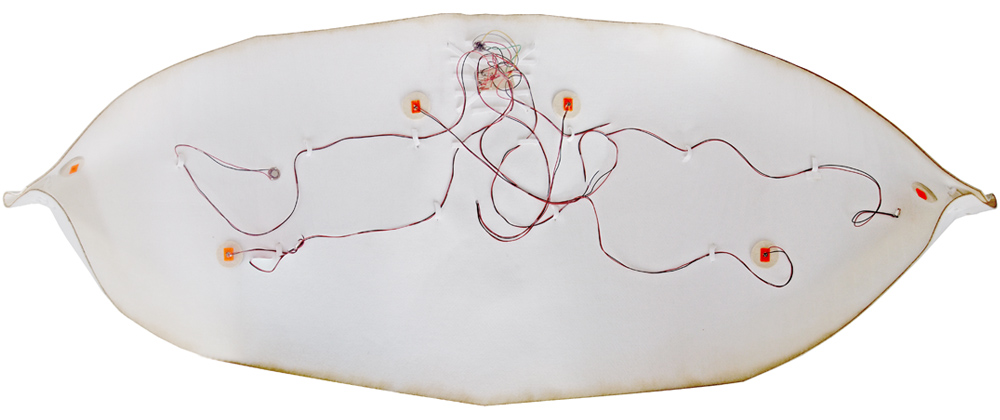

Buying the Cebek motors and new piece of thinner white felt today. We have to start the final prototype of this week. We have decided to laser-cut a new one. Booked our time at FabLab. 4pm. Due to the lack of time we agree to fabricate the wearable with identical digital pattern, this time without the elbow perforations. Electronic circuit on the breadboard with jumping cables is unstable so we decide to build a PCB shield on the top of the Arduino board and solder all wires onto it, so it can function while someone has the prototype on. New vibration motors need to have a protective cases which can be integrated into the felt. Using the transparent orange 3mm acrylic glass, we laser cut 5-piece box with simple joints, one for each motor. All laser-cut parts are complete by 6pm. Openings for motors are cut manually, small circle supports for motors are glued from the inside. Motors are being placed onto the felt parts which cover the most active areas – hands, elbows and shoulders.

Friday, March 15, IaaC

Early morning at IaaC. Sun rays are coming through the glass tile wall. No one is around. Today we need finish the prototype. First things first. There is still some work on the PCB board, which needs to be done. Wires controlling the motors are being soldered to the board along with ground ones. Reds and blacks.

The new felt prototype needs to have an additional layer which would keep the maze of cables in place. We cut a system of notches for elastic bands, which will hold the cables connecting the Arduino board with the vibration motors. All motors are in place now, along with boards and 3,7V battery.

Final testing starts now. Motors don’t work properly. Some of them work fully, others just idle slowly, the rest doesn’t work at all. There is a problem with power supply or problem with the PCB connections. Or both.

We test the motors one by one. It looks like it is a power supply problem. 6 motors just draw too much current. We decide to present the final prototype as it is right now, without working electronics. We put the idea of the motors reacting on the body movements on hold. At least for today.

close to the body | week 2 | making of video

close to the body | week 2 | final teaser

project team: Gemma Vila, Bert Balcaen, Rafael Vargas Correa, Martin Lukac

photo credits: Bert Balcaen, Rafael Vargas Correa, Martin Lukac

video credits: Rafael Vargas Correa