It is a fact that we have, for a long time, been moving away from the Fordist mass production system. In the past globalization’s effect segmented the production and assembly line in small parts and scattered them all around the world to follow raw materials and cheap labor. But today we are on the verge of a complete and utter revolution regarding the scale and way we produce commodities. It is the introduction of digital fabrication and computation in a completely different context that is bound to change the way we consume and fabricate goods in our cities.

It is most probable that in the nearby future every neighbor will have a small factory, the size of an apartment, where customers, or in other cases citizens, will be able to download designs of furniture, clothes, tools or whatever, customize them. or even generate them themselves and 3d print them, laser cut them or mill them, generally fabricate them exactly the way they want and need them.

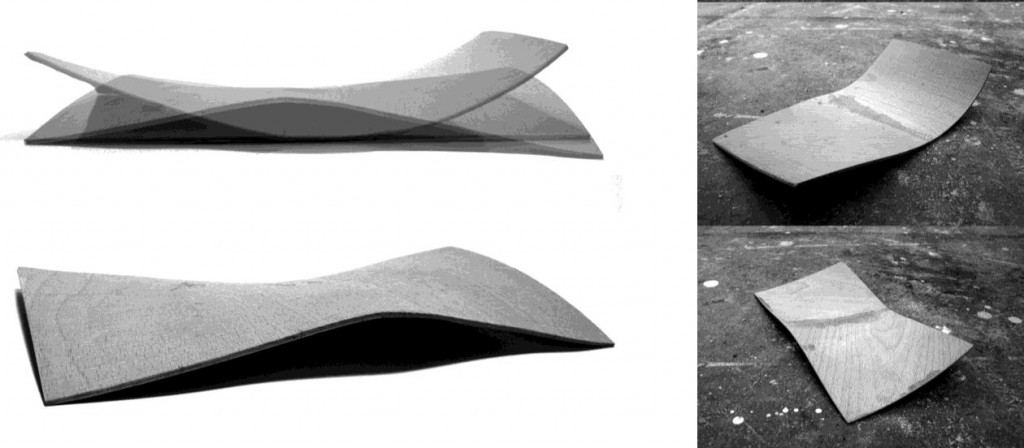

Mass production will and has to give way to mass customization and a more conscious and smart use of materials. The new technologies of fabrication, the modern computational techniques and the customization of production offer design a unique opportunity to explore the possibilities of new materials or new techniques of using existing materials and utilizing material behaviour to achieve better-smarter performance.