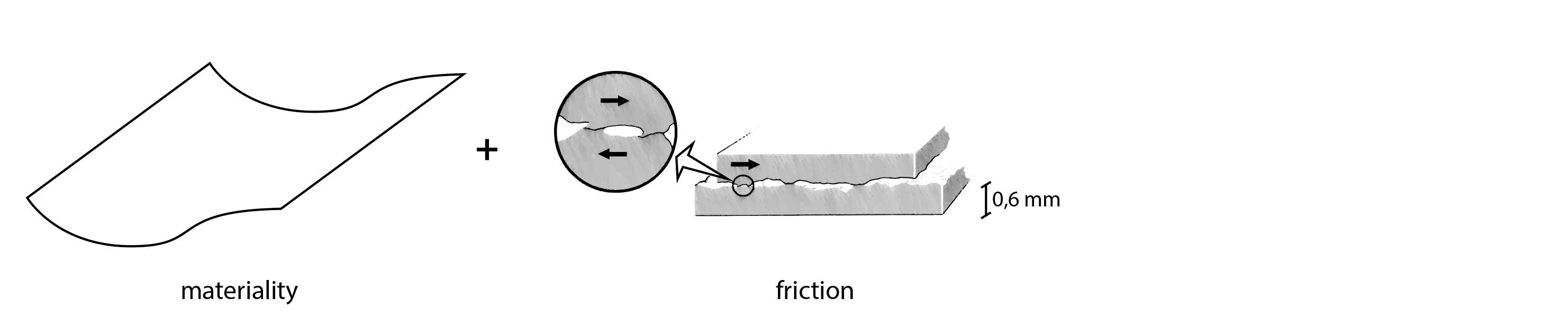

Poly-Pocket is a sticky spiral staircase of tensioned spring-capsules. The Individual components are held together using only tension members and friction enhanced by the “stickyness” of soft pvc plastic. The sticky pvc is laid over stiff polypropylene, which uses tension forces to hold the surfaces in active bending.

The video above shows the assembly process of the final model from our weekend workshop. The video below shows the process of computer-aided structural analysis, via the gh add-on Karamba. The Galapagos Solver of gh was used to find the lowest structural utilization among the possible combinations of geometric variables. The variables are applied to a single component, which associatively updates the global geometry.

[formula used for testing: (utilization percent range)*(square of utilization percent maximum)]

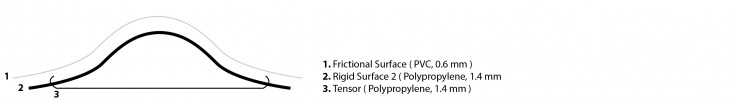

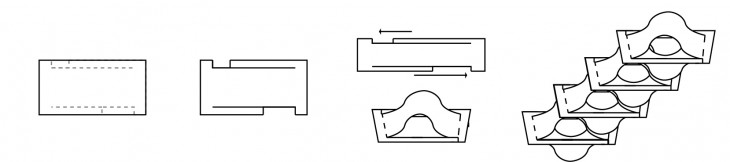

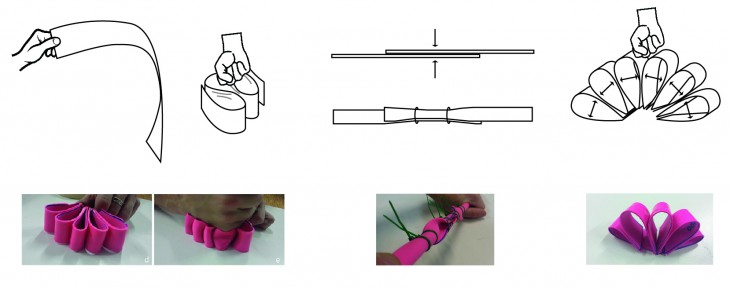

As stated above, the stair’s design follows principals from studies in the translation of soft materials to structural materials. These studies produced components which can oppose compressive forces, and implied a set of rules related to geometry, scale, and material properties. In the first case (pictured below), we see the technique of active bending used to enhance the 3-dimensional rigidity of an other wise flexible 2-d PVC sheet.

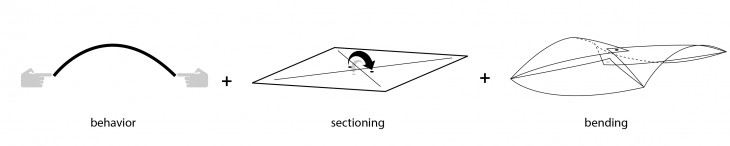

The second component (below) exhibits a different type of material manipulation based on the properties of sheet rubber, and seeking geometries which will compliment these properties. By understanding the relationship between tension-enhanced ‘vaulted’ geometries and the resultant spring-back effect observed in plastics, we can draw conclusions about the aggregation of both components.

The use of tension in connecting these components vertically takes advantage of both the spring-back effect and the surface ‘stickiness’ of plastic materials to create frictional resistance to shear forces without the use of direct connections between the surfaces of adjacent plastics.