IaaC Blog

OTF Blog

More Information:

OTF Previous Editions

2012 OTF – Light Hacker

Light Hacker is an accessory that “hacks” or modifies the behavior of an existing streetlamp. By using a sound sensor and a color filter that responds to ambient noise, Light Hacker changes the color of the emitted light. The device also has a stand-alone internet connection allowing to send real-time sensor readings to an internet server (COSM), providing open data for the development of noise maps and computer software useful for planners, researchers and citizens. It can be reused, transported and installed where required.

Read More

Read More

Posted in Renato Avila Claro Leave a comment

OTF Projects: New Prosthesis – Exoskeletons

New Prosthesis Exoskeletons

The New Prosthesis project uses digital fabrication techniques to cut and bend wood into lightweight and materially efficient structures. These pieces are bent without form work, using the specific control of the laser cutter to define joints instead, thus avoiding wasteful form work.

OTF Student: Joel Letkemann

Posted in OTF 2010 Leave a comment

OTF Projects: Sunscreen

¨Sunscreen¨

Sunscreen is a passive solar display system intended for a wide range of architectural applications. The system can be programmed to relay messages or animations depending on the location of the light

source (either the sun or artificial lights). To realize Sunscreen, I collaborated with Kuka, using one of their six-axis robotic arms tofabricate numerous tests. The final large-scale prototype is a solarclock that responds directly to the position of the sun, 365 days of the year here in Barcelona.

OTF Student : Brian Peters

Posted in OTF 2010 Leave a comment

OTF Projects: Respira

“RESPIRA” the breathing wall

Respira, is a two dimensional panel that works like skin protection and responsive facade, that will change its shape according to the outside temperature and help the air ventilation or protection of the building.

OTF Student : Ilaria La Manna

Posted in OTF 2010 Leave a comment

OTF Projects: PNEUMorphosys 0.2

PNEUmorphosys 2.0 is a CNC formwork system based on the use of pneumatic force. Different air pressure is applied individually to a series of elastic pockets that shape an elastic membrane inside of which the material is poured. As opposed to traditional formwork, that produces a great amount of waste (each shape = new mould), PNEUmorphosys can be used to produce multiple variations without any additional fabrication process. The digital control allows the use of different design or performative inputs and at same time helps the material distribution, using the pneumatic force to push the material trough the membrane.

OTF Students: Brian Miller, Natalija Boljsakov

Posted in OTF 2010 Leave a comment

OTF Projects: WallSystem

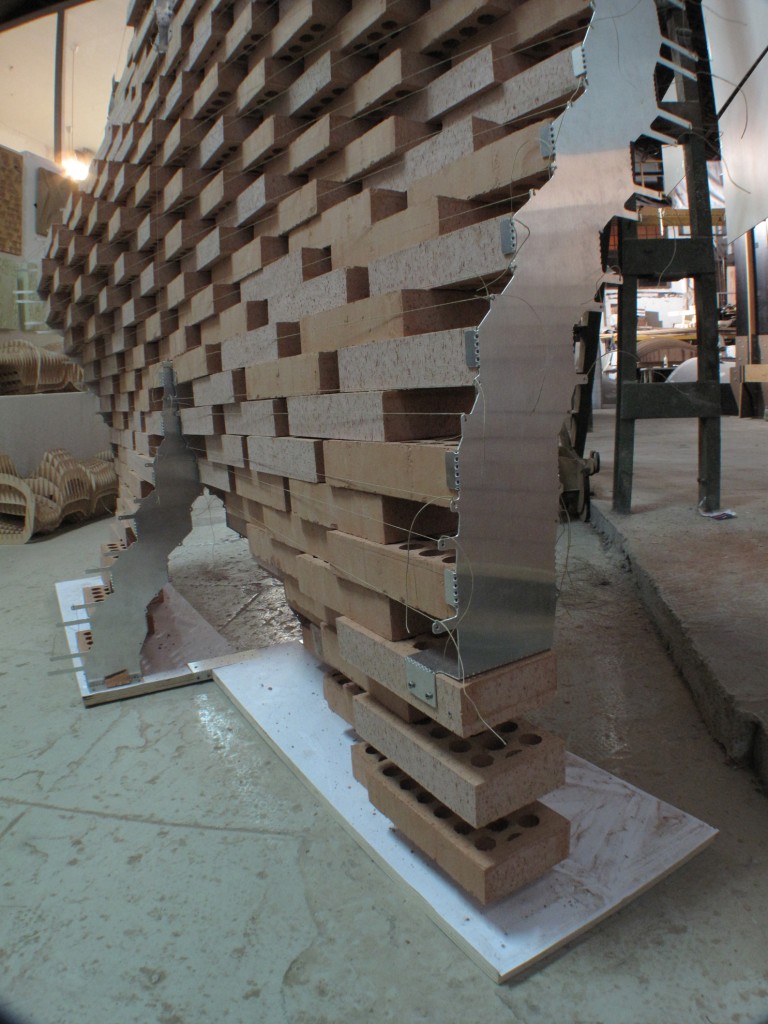

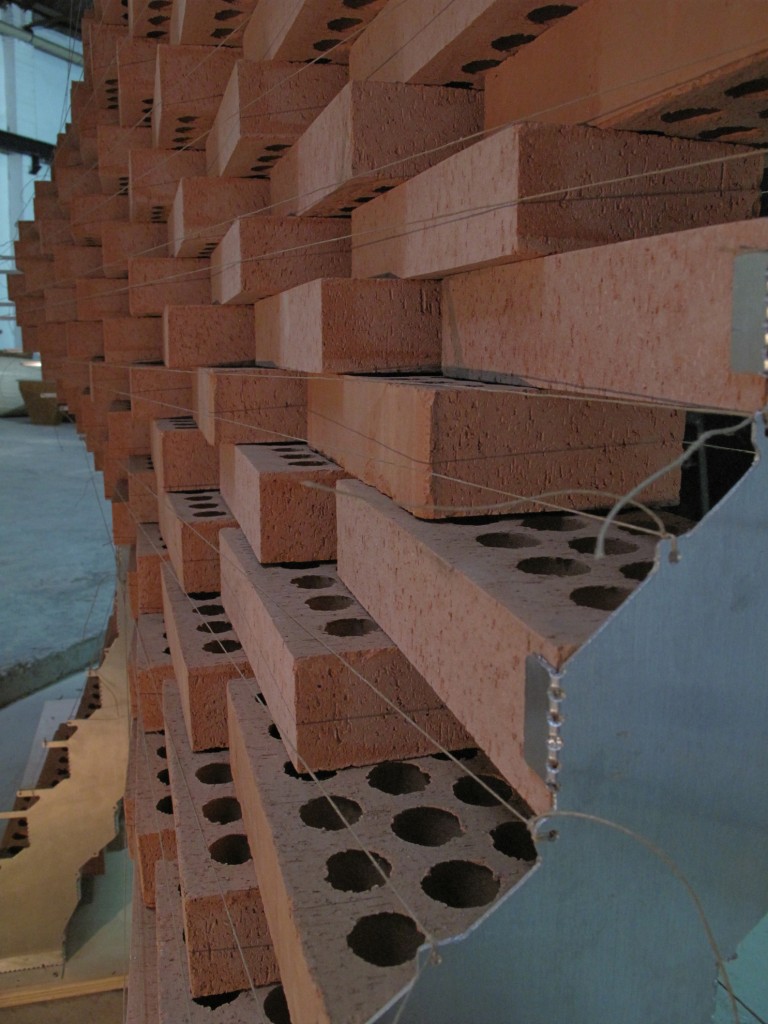

Wall System

This project is an investigation on similar units structures by strategically inserting edges. The materiality and performance of the assembly which is suggested by this combination is tested with a prototype. Trying to optimize for manual assembly,I tried to approximate the randomly defined surfaces so that I will be able to use linear segments to assemble the bricks. This approach did not work as the approximation resulted in unacceptable offset between consecutive layers.

¨In trying to optimize for manual assembly , I tried to approximate the randomly defined surfaces so that I will be able to use linearsegments to assemble the bricks.This approach did not work as the approximation resulted in unacceptable offset between consecutive layers.¨

OTF student: Alemseged G Bishu

Posted in OTF 2010 Leave a comment

OTF Projects: Bloon

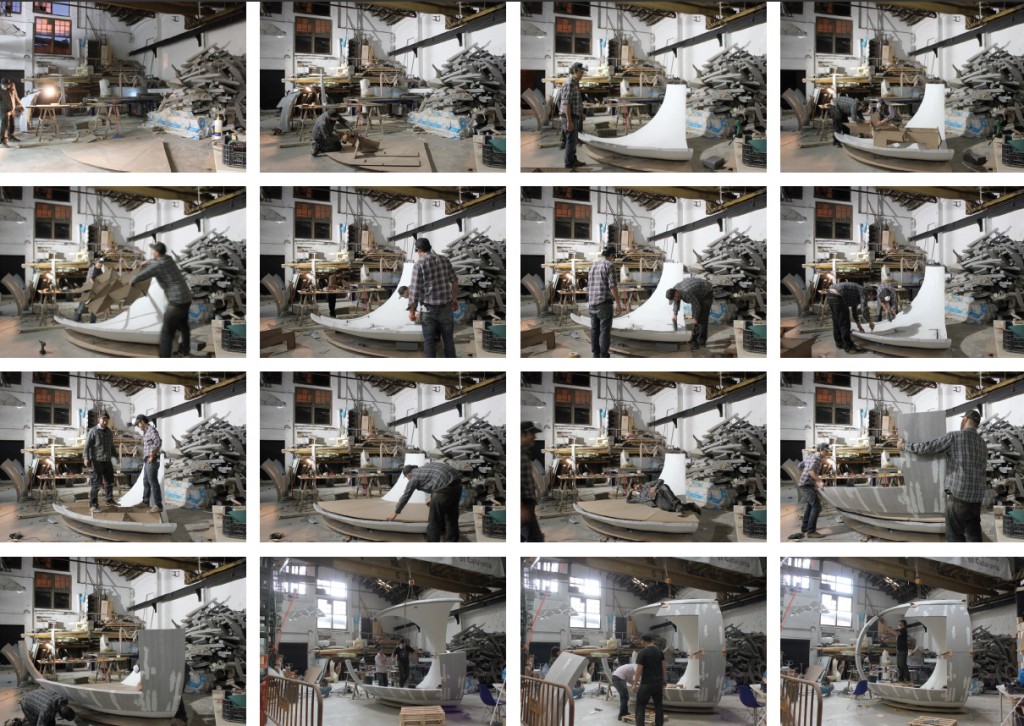

Bloon

The research project for OpenThesis Fabrication 2010 is a collaboration between IAAC and Barcelona based space tourism company, Zero 2 Infinity.Their project, Bloon is a capsule that will travel to near space giving travellers the experience to view our planet in the most unique way. The four hour flight begins with a one hour ascent using an air balloon, followed by a 2 hour cruising phase at an altitude of 36km, with the final hour cruising back to the landing area using a parafoil. The capsule holds 4 passengers (plus 2 pilots) and has the benefits of zero emissions, no noise, no training sessions (anybody can travel), and will be powered by batteries and inert gas. The project for OpenThesis concentrates on the space capsule: the geometry, possible fabrication processes, and building a 1:1 prototype. The first phase consists of understanding the geometry of the capsule (a torus) supported by research in composite structures such as Automatic Fiber Placement technologies (AFP), and finally building a lightweight 1:1 prototype of one section of the capsule to be used for long term research into the design and fabrication of the capsule.

OTF Student: Nicholas Waissbluth

Posted in OTF 2010 Leave a comment