Category Archives: Jayant Khanuja

Group – 4_ Lamp (Bamboo+Resin)

Also posted in Mehmet Yilmaz Akdogan, Neel Kaul, Shashank Shahabadi Comments closed

Milling

- Glowing Sphere

The Cast was made with foam board using milling machine. Teflon was sprayed so that liquid resin doesn’t stick to the the foam. Bamboo fibers are randomly kept inside the foam and the form was closed and resin was poured from a hole from the top.

Also posted in Mehmet Yilmaz Akdogan, Neel Kaul Comments closed

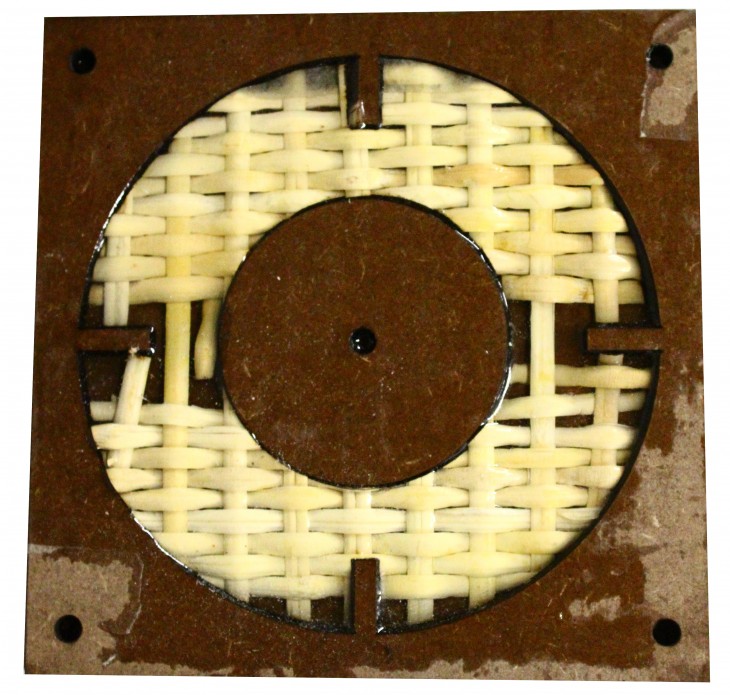

Laser Cutting

The Resin hardened and got stuck to the board.

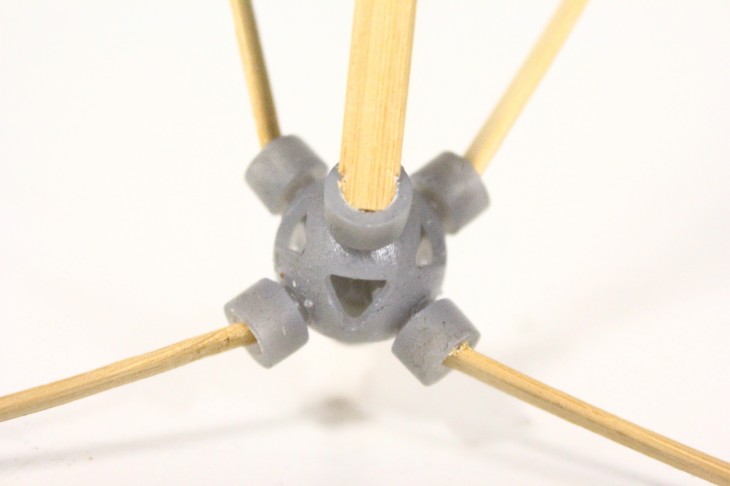

3d printing

Also posted in Mehmet Yilmaz Akdogan, Neel Kaul Comments closed

Acrylic

Acrylic Properties (PMMA)

| Product Description | ||||

|

This data represents typical values that have been calculated from all products classified as: Generic Acrylic (PMMA)This information is provided for comparative purposes only.

|

||||

| General | ||||

| Material Status |

|

|||

| Availability |

|

|||

| Physical | Nominal Value | Unit | Test Method |

| Specific Gravity | |||

| – | 1,14 to 1,20 | ASTM D792 | |

| 73°F | 1,15 to 1,20 | g/cm³ | ISO 1183 |

| Apparent Density | 0,65 to 0,71 | g/cm³ | ASTM D1895 |

| Melt Mass-Flow Rate (MFR) | |||

| 230°C/3.8 kg | 0,50 to 8,3 | g/10 min | ASTM D1238 |

| 230°C/3.8 kg | 0,30 to 5,6 | g/10 min | ISO 1133 |

| Melt Volume-Flow Rate (MVR) (230°C/3.8 kg) | 0,0380 to 0,293 | in³/10min | ISO 1133 |

| Spiral Flow | 9,27 to 15,4 | in | |

| Molding Shrinkage | |||

| Flow : 73°F | 3,9E-3 to 6,4E-3 | in/in | ASTM D955 |

| 73°F | 0,40 to 0,60 | % | ISO 294-4 |

| Water Absorption | |||

| 73°F, 24 hr | 0,29 to 0,42 | % | ASTM D570 |

| 73°F, 24 hr | 0,30 to 1,9 | % | ISO 62 |

| Equilibrium, 73°F, 50% RH | 0,30 to 0,37 | % | ISO 62 |

| Mechanical | Nominal Value | Unit | Test Method |

| Tensile Modulus | |||

| 73°F | 184000 to 512000 | psi | ASTM D638 |

| 73°F | 342000 to 500000 | psi | ISO 527-2 |

| Tensile Strength | |||

| Yield, 73°F | 5420 to 10700 | psi | ASTM D638 |

| Yield, 73°F | 5370 to 12100 | psi | ISO 527-2 |

| Break, 73°F | 2800 to 10900 | psi | ASTM D638 |

| Tensile Elongation | |||

| Yield, 73°F | 2,4 to 5,2 | % | ASTM D638 |

| Yield, 73°F | 3,6 to 25 | % | ISO 527-2 |

| Break, 73°F | 0,20 to 15 | % | ASTM D638 |

| Break, 73°F | 1,8 to 7,2 | % | ISO 527-2 |

| Nominal Tensile Strain at Break (73°F) | 9,9 to 27 | % | ISO 527-2 |

| Flexural Modulus | |||

| 73°F | 188000 to 512000 | psi | ASTM D790 |

| 73°F | 174000 to 508000 | psi | ISO 178 |

| Flexural Strength | |||

Posted in Jayant Khanuja Tagged http://plastics.ides.com/generics/3/c/t/acrylic-properties-processing Comments closed