milling 0.6mm thick steel

Category Archives: Zunabath Abdul Majid

milling exercise

3D Printing Universe

Sphere Fabrication

Crude Steel 0.6mm

Digital Fabrication – Material Research

MATERIAL - Crude Steel 0.6mm thick sheets (Minerals)

SCIENTIFIC NAME

Crude steel does not have a scientific name since it is a mixture of carbon and iron

FORMULA / CHEMICAL COMPOSITION

Fe + C

MATERIAL DESCRIPTION

-

Iron that has been decarburized (process of converting molten iron into crude steel by reducing its carbon content) but has not yet been refined into a definite steel grade.

-

This is the first solid state of steel after melting also referred to as raw steel.

-

A non-alloy steel by definition as it does not yet contain specified amounts of any alloying element.

-

As this description is based only on visual inspection this sheet could be one of the 3 categories of non- alloy steel; low carbon steel/mild steel (<0.3% C), medium carbon steel (0.3 to 0.6% C) or high carbon steel (>0.6% C). While 90% of steel produced are non-alloy, the larger share is taken by mild steel.

*Statistics reference from: http://pib.nic.in/newsite/erelease.aspx?relid=34828

EXTRACTION PROCESS

Most steel is made thru one of two basic ways:

-Integrated (blast furnace and basic oxygen furnace).

-Electric arc furnace (EAF).

The integrated route uses raw materials (that is, iron ore, limestone and coke) and scrap to produce steel. The EAF technique uses scrap as its prime input.

The EAF method is much simpler and faster since it only requires scrap steel. Recycled steel is led into a furnace and re-melted along with some other additions to produce the end product.

In modern machines molten steel is straight away processed and cut into either thick or thin slabs depending on the need for it. As for thinner more precise measurements like the 0.6mm thick sheets, thin slabs are flat rolled in rolling mills.

BASIC PROPERTIES

Compressive Strength (N/M2): 170,000,000 – 310,000,000

Tensile Strength (N/M2): 480,000,000 – 620,000,000

Stiffness (N/M2): 200,000,000,000

Density (KG/M3) : 7,750 – 8,050

Carbon Footprint (Average KGCO2E/KG): 2.5

Recyclable: Yes. Steel’s unique magnetic properties make it an easy material to recover from the waste stream to be recycled. The properties of steel remain unaffected no matter how many times the steel is recycled. Steel is the world’s most recycled material.

Laser: Yes

Small Laser: Yes

Milling: Yes

3D Printing: Yes

ADVANTAGES IN THE CONTEXT OF DIGITAL FABRICATION

-

One of the most favourable properties of steel is that the required strength can be attained through the fabrication process depending on the end product and its use. This is because the crystalline structure is manipulated throughout the heating and cooling.

-

Fixing can be either mechanical or through fusion

-

Can be cast into molds in molten state.

-

Allows forging and stamping: forging is heating until plastic and then beating into shape whereas stamping is achieving the desired shape by squeezing sheets between matching dies.

-

Sawing, shearing and punching.

-

Steel is very friendly to the environment. It is completely biodegradable, holds great durability, and, compared to other materials, requires comparatively low amounts of energy to produce. Steel plates can be used on several machines including CNC milling and Laser cutting machines. Since steel is a widely used material the steel industry has made huge efforts to limit environmental pollution in the last decades.

MATERIAL SUPPLIERS IN BARCELONA

-

Servei Estacio – Arago, 270-272, 08007, Barcelona, Spain

6.90 Euro – 500x250mm sheet of thickness 0.6mm

http://www.mwmaterialsworld.com/es/

PROJECT REFERENCES

-

Norwegian wild reindeer centre pavilion (2011)

Minimalist Rectangular House: temporary shelter for visitors who come to listen to lectures about the unique nature and history of plateau Dovre Mountain.

Location: Hjerkinn, Norway

Designed by: Snohetta AS Oslo

Read more on: http://www.worldbuildingsdirectory.com/project.cfm?id=3423

photograph by: Klaas Van Ommeren

-

Reading Between the Lines (2011)

Transparent Steel Church: 34 ft. tall steel church made out of 100 stacked layers of steel and 2000 steel column plates

Location: Looz, Limburg, Belgium

Designed by: Gijs Van Vaerenbergh

Read more on:

http://www.archdaily.com/298693/reading-between-the-lines-gijs-van-vaerenbergh/

Image References : http://www.mymodernmet.com/profiles/blogs/transparent-steel-church

-

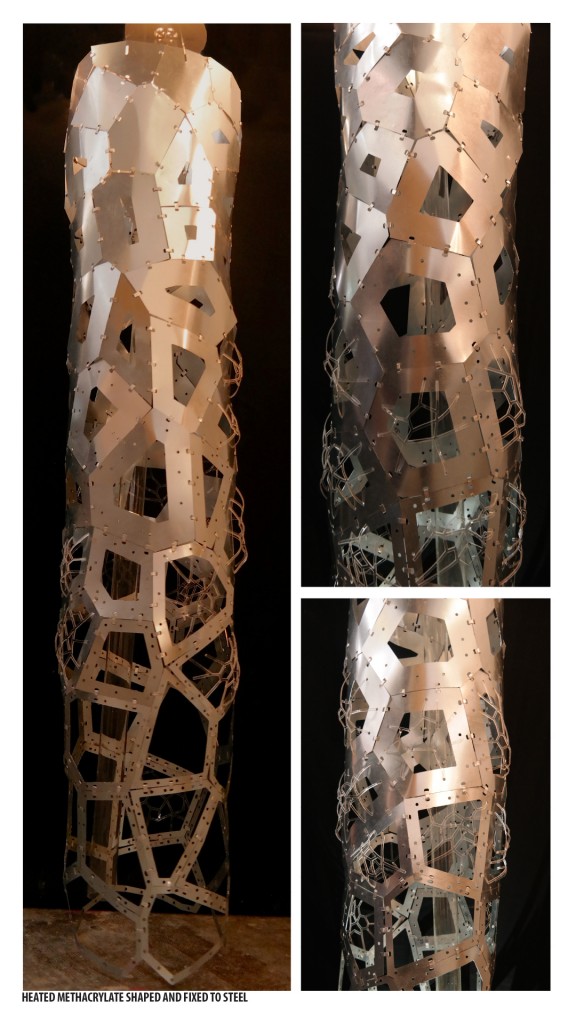

Ninety Nine Failures Pavilion – Digital Fabrication Lab (DFL), University of Tokyo

Completed : November 24th, 2013

Structure: Freeform Surface Tensegrity Structure

Material: Compressive Components: Stainless Steel Plates with 0.5 mm, 0.8 mm, 1.2 mm, 1,5Mm Thickness

Tension Cables: Stainless Steel Cables in 3 mm diameter Base ring:

Base ring: Stainless Steel pipe 48 mm in diameter

Foundation: Precast Concrete blocks

Furniture: Painted plywood Weight 1.5ton (upper structure in stainless steel), 1ton (concrete foundation)

Link: http://www.toshikatsukiuchi.com/?page_id=1043