Category Archives: Michelle Tzuman Tseng

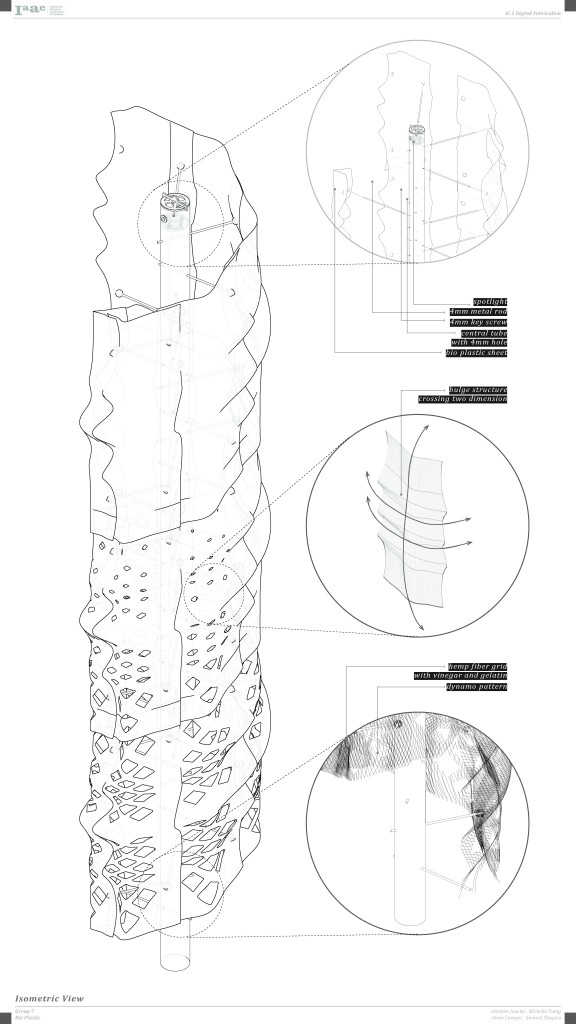

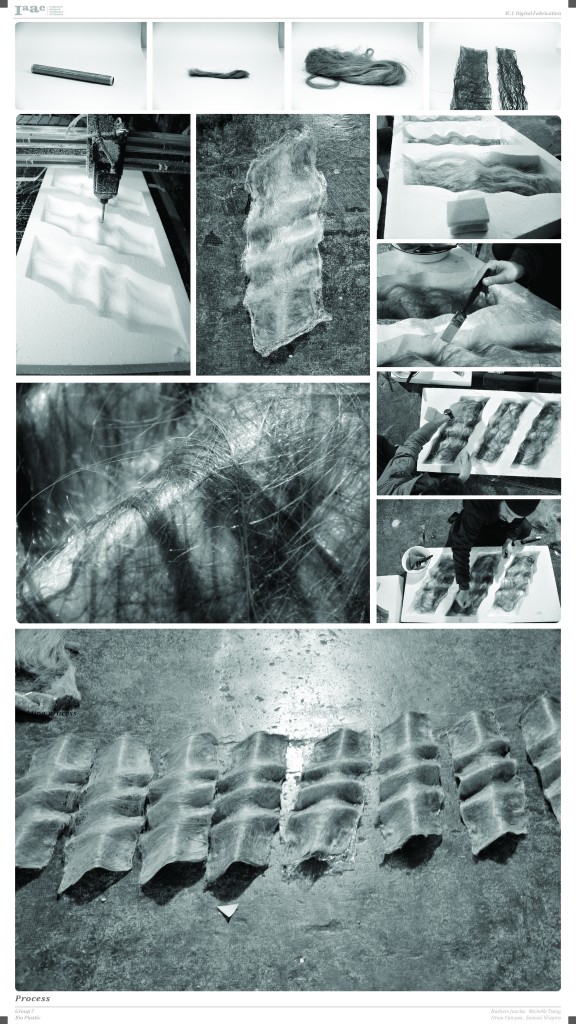

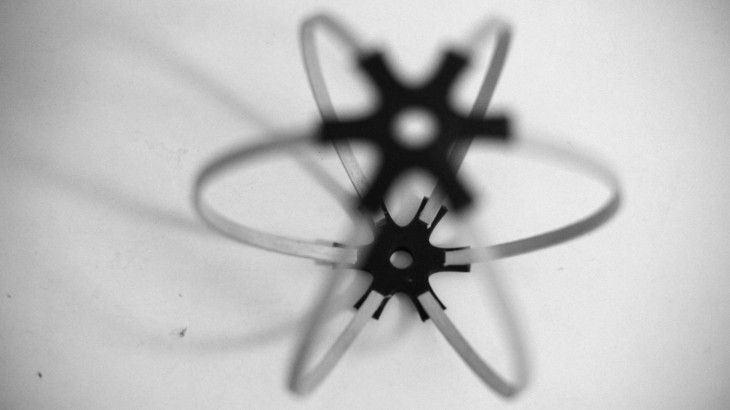

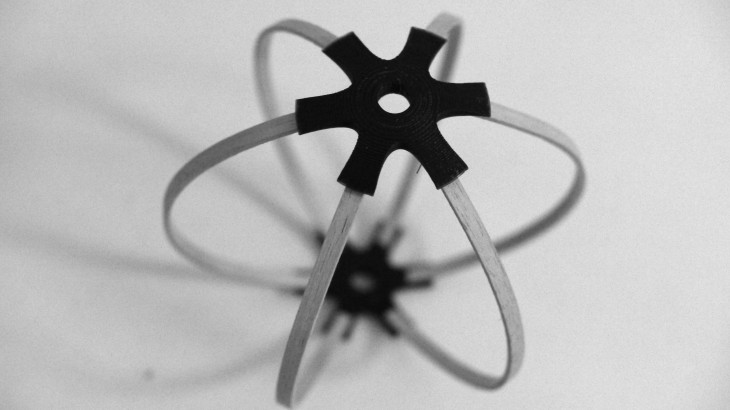

Bio Plastic Lamp

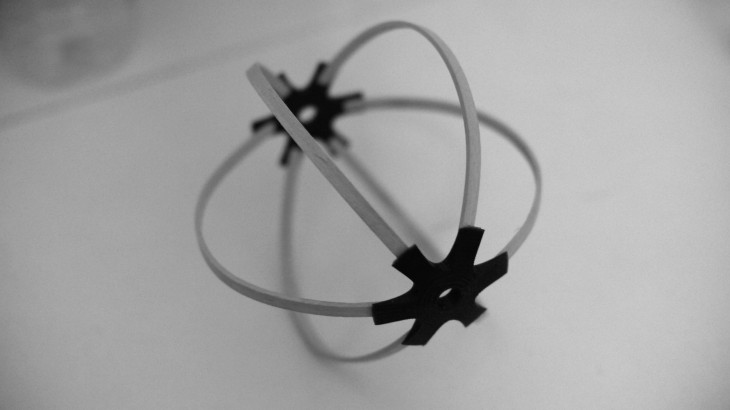

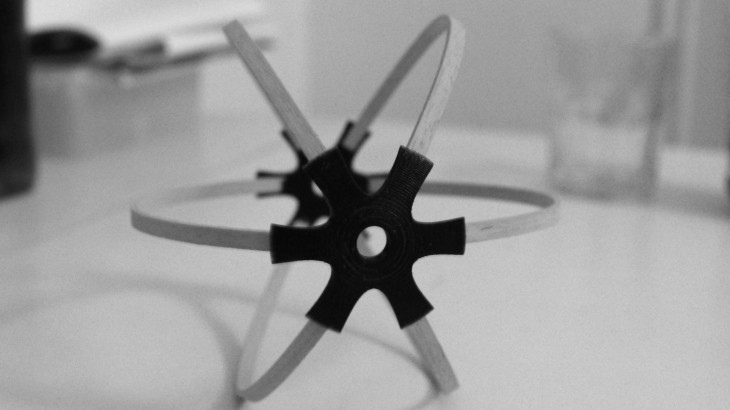

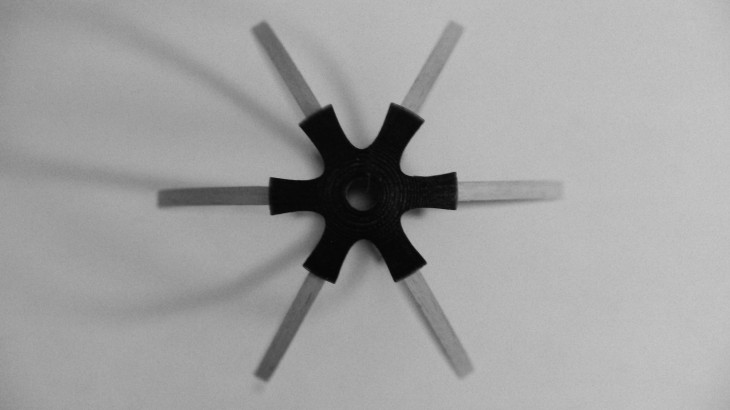

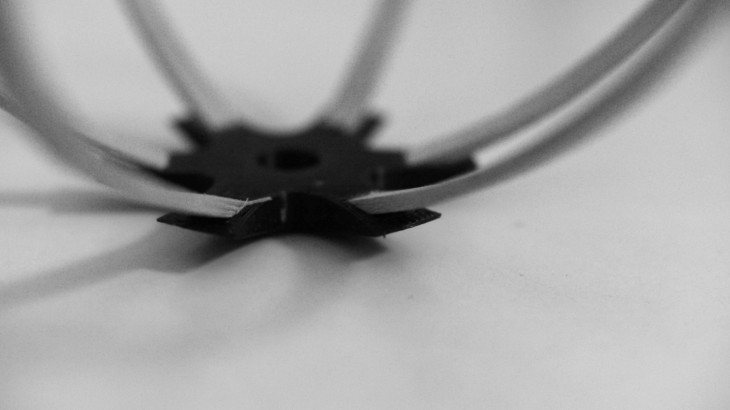

3d printed joints

Bio Plastic Research

The research was based on the project made last year in iaaC, which explored the production methods and material behaviors in plastic biodegradable systems. It investigates DIY biomaterial production and passive reconfiguration processes to create components for a dissolving architecture.

The Bio Plastic research was made by Sviatlana Matushko, Mardet Gebreyesus, Dhwani Patel, under the tutoring of Areti Markopoulou and the assistance of Alexander Dubor and Moritz Begle.

At this class we tried through a series of tests with different tools of digital fabrication machines and through a series of experimentation of ways of assembling and making the materials to be transformed later, into a lamp.

Salty Rice Clay

MATERIAL DESCRIPTION

Salty Rice Clay made by equal- ratio mixing salt and Thai glutinous rice at room temperature.

The glutinous rice creates the super-strength mortar, this organic-inorganic compound was made possible by amylopectin, a type of polysaccharide, or complex carbohydrate. The amylopectin combines with the inorganic calcium carbonate from the lime to form a mortar that has more stable physical properties, greater mechanical strength. It has been found more stability by adding the salt (sodium chloride) with glutinous rice to creat a material with ductility, but also the ability to maintain a certain shape.

EXTRACTION PROCESS

1. Blend the rice and sea salt and filter it into a container as the rice clay.

2. Boil the rice with sea salt then stir until it become a paste.

3. Mix the salty rice clay with the rice paste.

4. Test the potential of the salty rice clay.

Link- http://vimeo.com/109538291

BASIC PROPERTIES

Compressive Strength (N/M2)-

Tensile Strength (N/M2)-

Stiffness (N/M2)-

Density (KG/M3)-

Carbon Footprint (Average, KGCO2E/KG)-

Recyclable- YES

Laser- NO

Small Laser- NO

Milling-

3D Printing- YES

Advantage In The Context Of Digital Fabrication

Salty Rice Clay is low cost, translucent and totally organic. It can be post processed for increased strength and durability by mixing with other fabric.

MATERIAL SUPPLIERS

Alimentacion Fei He

C/Tamarit 148 TD 2, 08015 Barcelona

934262985

PRICE (€/KG, CHEAPEST FOUND IN BCN, 2014)

3€/KG

MATERIAL PHOTOS

MATERIAL REFERENCE PHOTOS WITH INFOS AND LINKS

Link1- Sticky rice holds ancient Chinese buildings together

http://news.nationalgeographic.com/news/2010/06/100608-sticky-rice-mortar-china-science/

Link2- 3D printing salt

http://www.3ders.org/articles/20130413-exploring-7-materials-with-3d-printing.html

Link3- Rice paper mache

http://seekingwings.wordpress.com/2012/05/07/rice-paper-mache/