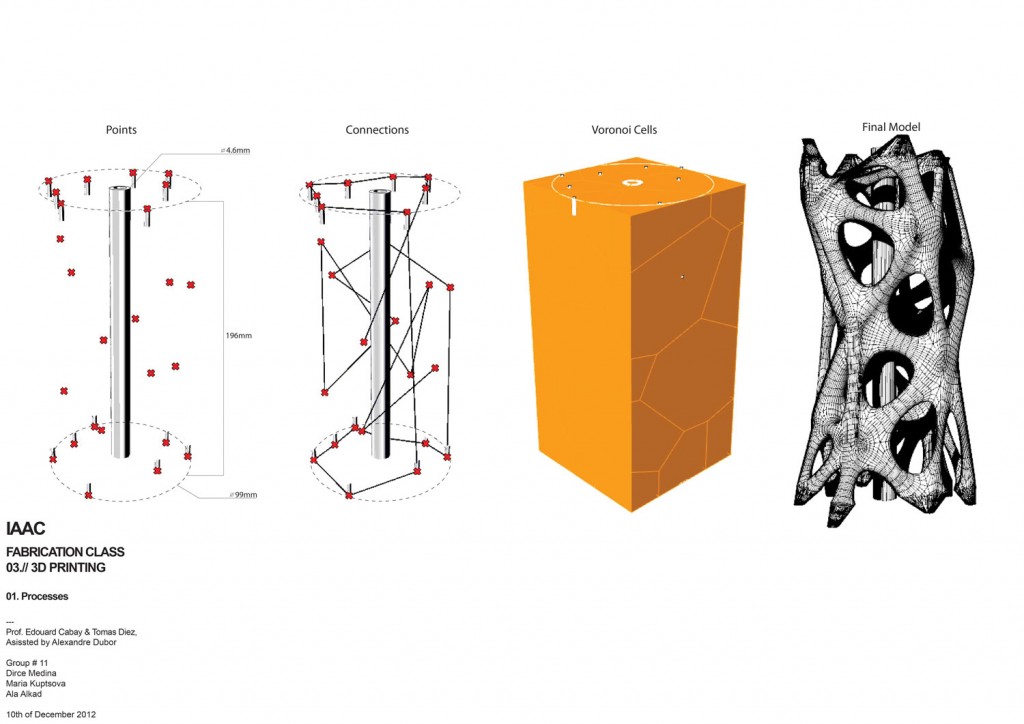

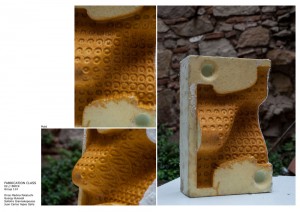

The project consist in the design and manufacturing of a piece which had to fit within a cylindrical bounding box of 49.5 mm diameter and 200 mm height. It was necessary to respect a central core consisting of a 3mm thick tube with a 3.75mm radius hollow space at its center.

The principal aim was the structural and material optimization, working primarily in an anticlockwise direction.