The project consisted in creating a model for 3D printing a piece of 200 x 100 mm.

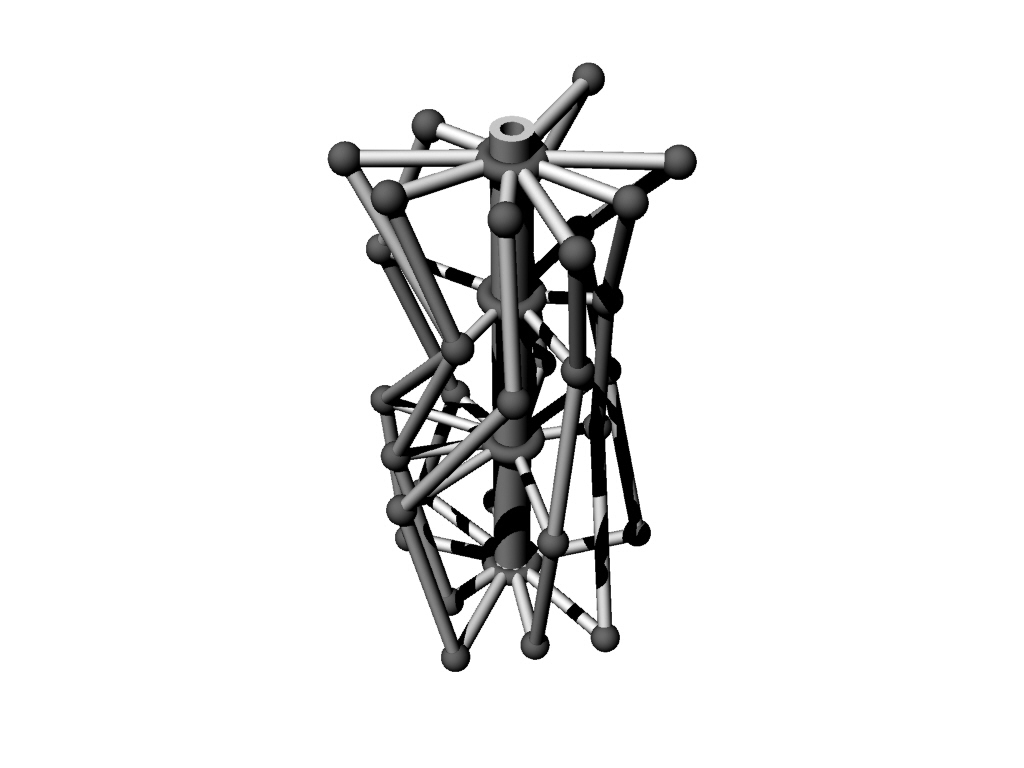

During the first phase, the group tried to connect the points that were given, into a structure that created notorious vertical triangles, that were connected at the top and bottom, to the vertical beam.

The second phase, started after talking to the professors, when we realized that the structure of the piece needed to be reinforced because of its fragile materiality, it scale, and because our group is almost at the bottom of the installation, the piece would be supporting the rest of the other pieces.

Therefore, the width of the connector points was amplified, also the width of the pipes, and the simple vertical triangles, became a sort of molecular structure, that attached every vertical piece four times to the vertical beam.

Group 2: Surag Viswanathan, Yousef Al Nafisi and Gabriela Gonzales Faria