Group 25 – Laser cutting

Group 05 / Brick Design

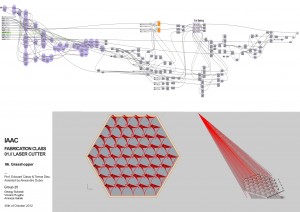

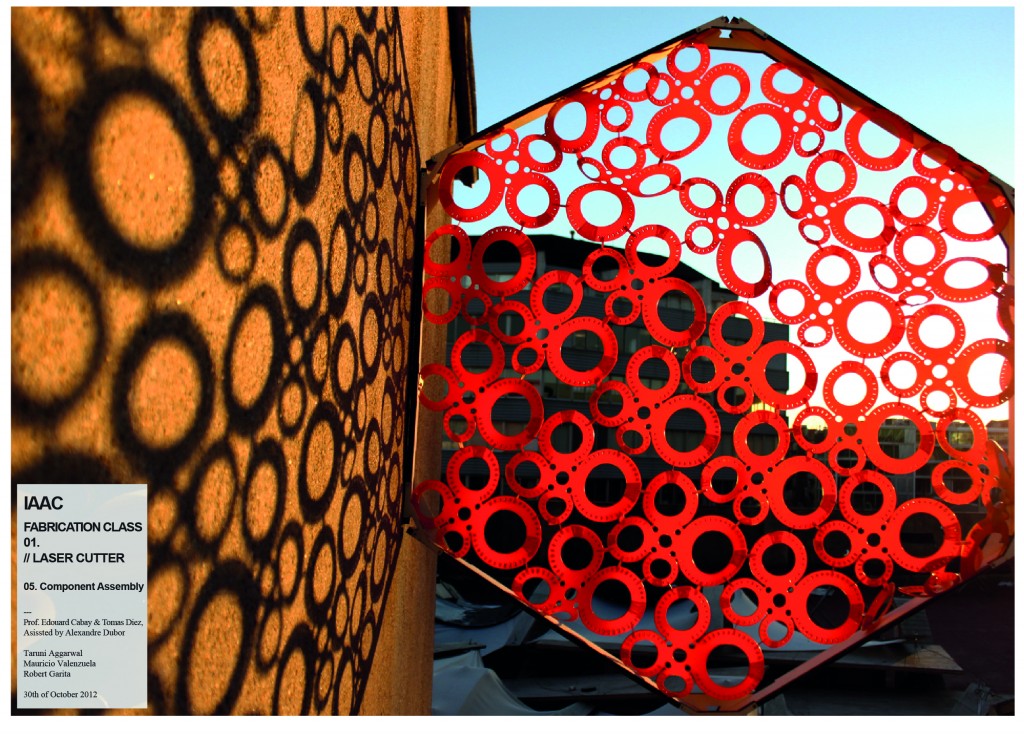

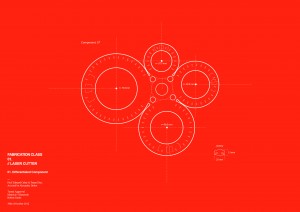

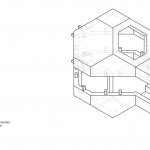

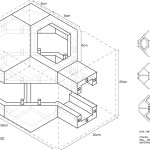

Group 19 Bending / Digital Fabrications

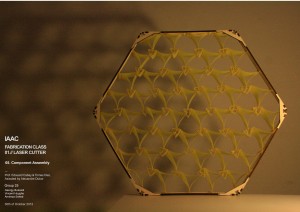

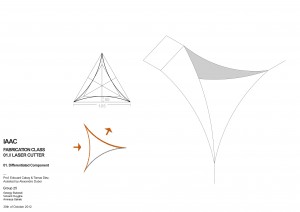

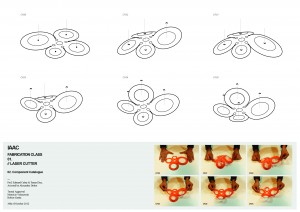

The aim was to use bending in order to create variations in the component. The organic shape of the component enables us to create different variations with a one single component. The joinery detail is simple but at the same time efficient which keeps the whole assembly intact within the hexagon.

Mauricio F Valenzuela Lanzas Robert Francisco Garita Garita Taruni Aggarwal

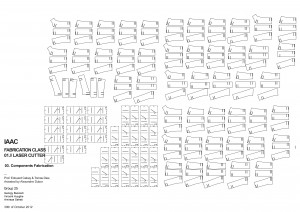

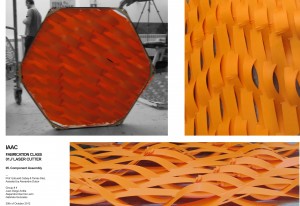

Group 1_Laser Cutting

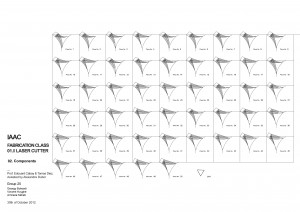

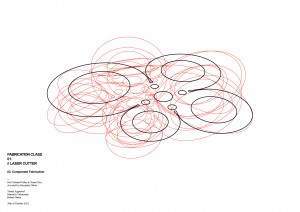

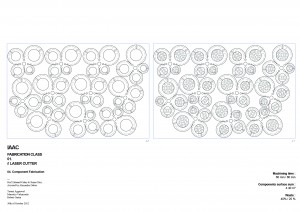

The assignment consisted in fabricating, through the laser cutting machine, a installation that should fit a hexagon of approximately 1 meter width.

The installation had to be visually connected to the light entrance of the window located in IAAC’s administration office. The material assigned, was polypropylene, 0.8 mm width, opaque orange color.

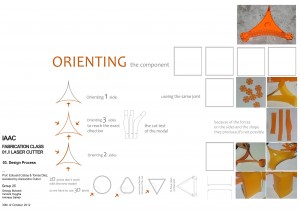

Once, the group started to work with the material, we realized how flexible it was, so in order to stabilize it, for the scale of the hexagon, we developed the concept of a fabric, with “x” and “y” axis.

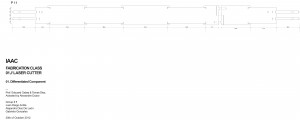

The process of design was complex mostly because of its joinery.

Finally, the fabric ended up having only one axis, with parameters assigned to each piece of it, for accomplish the light direction objective. Each piece had female-male parts, so that the joinery would succeed to create a stable fabric.

Group 1: Alejandra Diaz de Leon, Juan Diego Ardila, Gabriela Gonzales Faria