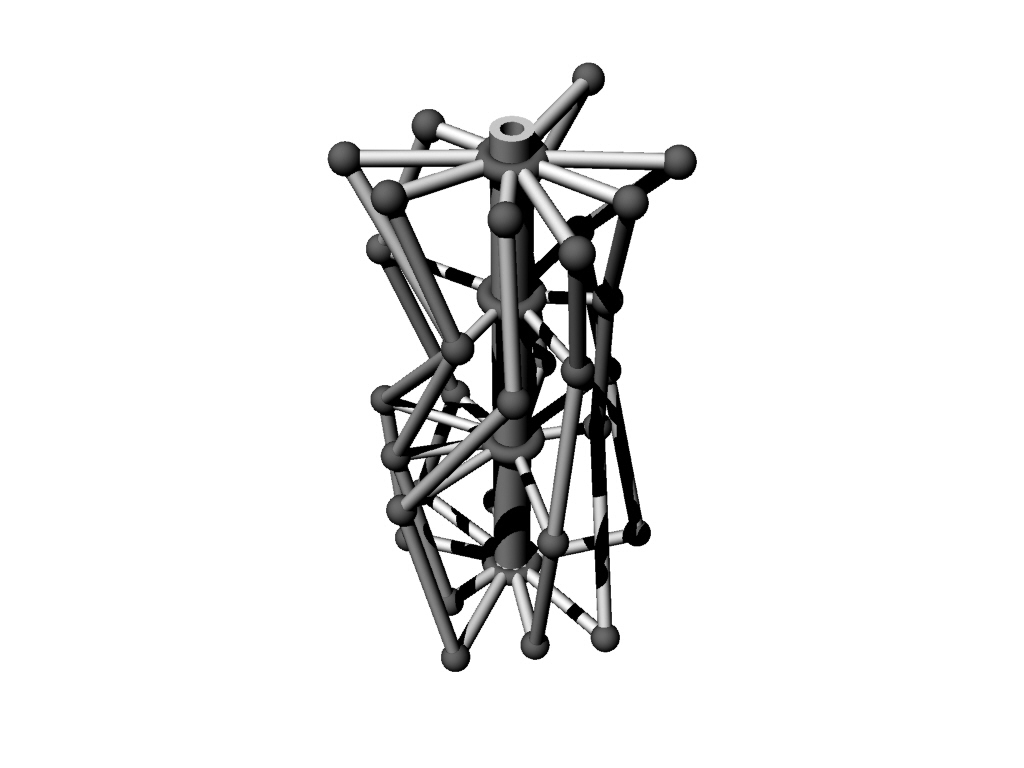

An oblique structural system that it’s transferring the load in two different ways, internal one by the middle core supported with a vertical columns around it and external one by the trusses on elevations, and both related with 6 levels of beams that it’s changing the angle in the inner void from the top till the bottom depending on the height in the tower, to give at the end a very high stability for the entire form.

Aldo Sollazzo Nasr Chamma Giannakopoulous Sofoklis