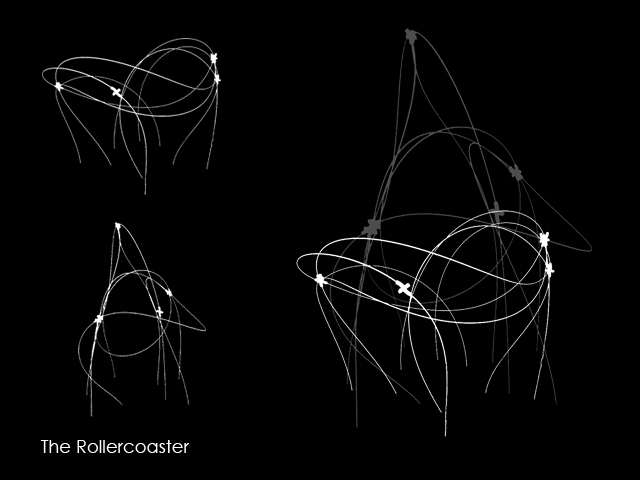

The idea of Rollercoaster was to achieve two configurations by sliding and locking into position the joints fabricated in the 3D printer. Four joints were created by twisting a pipe which would be joined with itself to create different angles of sliding as well as different amounts of cables running through. This joints would then be coupled with each other by a female-male joint that, aided by the tension of the wire, would lock in place. The different configurations would be achieved by clipping different joints together and sliding the wires to change the inflection point.

Several problems came evident once the joints were printed. First was that the female-male clip lost its precision when printed so it didn’t hold and second, the size of the joint was too small and the wire wasn’t able to bend so sharply. Given the setback, we turned the sliding joints into clipping joints which still allowed us to change the direction of the cable by segmenting it. This demonstrated the versatility of the joint by changing its function and its ability to create different shapes by using the variety of angles in it.

The shapes then were created by changing the insertion point in the board (maintaining the same holes for both configurations) and by joining the cables in different nodes in the joints.