When designing the pattern for our tile, we examined the behaviour of raindrops, and the effect they have when hitting the tiles of Barcelona.

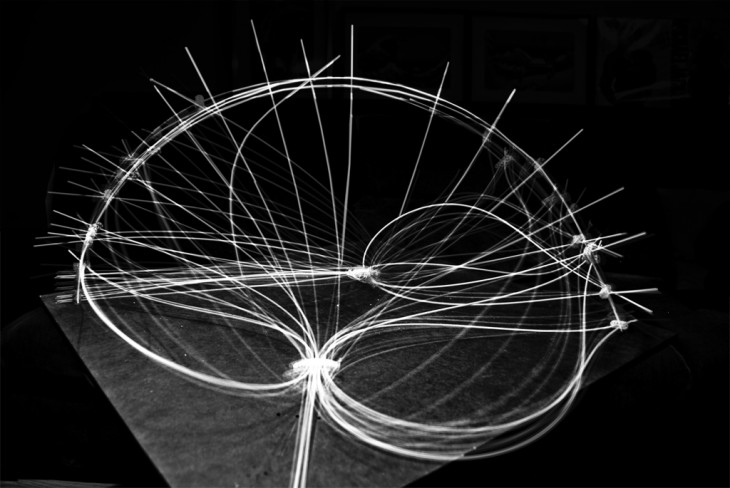

Creating ripples in the concrete, we duplicated the intricate patterns of the raindrops within our design. These patterns flow through the four tiles that we created. Using a variety of larger and smaller scale curves, these spirals join together to form one continuous pattern.

This liquid surface was then imported into RhinoCam where it was adapted to the form and dimensions of the tile. RhinoCam was used in order to create the spiral effect on the tiles surface.

Once this stage was complete, the milling process begun. From the produced mould, we then filled it concrete and allowed it to dry, resulting in four intricate tiles.