GroupTEN approached brief of the 3D printing excersize with a vision to create a kinetic, 3-Dimensional form, exploiting all of the properties of the given materials. This was no doubt the approach taken by all other groups. So what made us different?

We did not look at creating a structure, or a string of points. We instead looked at creating a malleable surface. A moving geometry which would flow and adapt based on the applied forces.

Post Research & Design stage, we moved into understanding the techniques involved in 3D printing. A Rhino file was simple enough to draw, with numerous joints developed – each designed to test minimum tolerances of the printing material, both in terms of breaking and connecting to the plastic rods.

Sadly time ran short for our project, and our test pieces were not able to be printed.

Alas, we were able to print our pieces and explored the various assembly approaches available to us. Having a very simple and adaptable piece of geometry repeated many times allowed us to experiment with the form until we were happy.

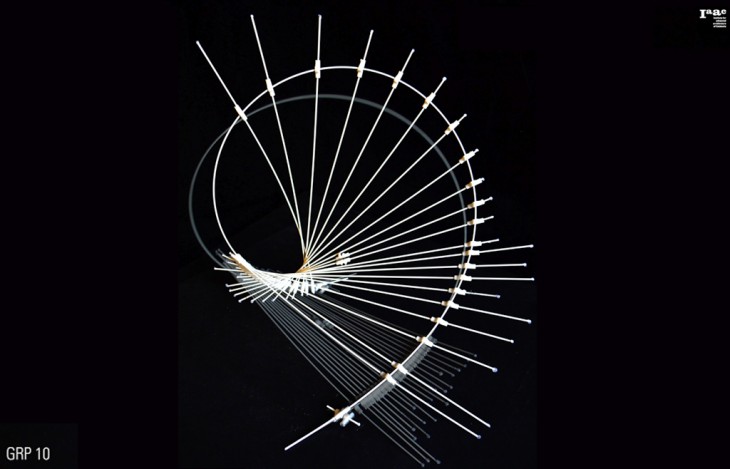

This experimentation began with a single spine, from which all rods would meet at a perpendicular angle, and spin around. This created a form which was random and chaotic. Although the printed pieces were designed to limit the movement of each one next to it to 10°, the tolerance of the machine rendered this feature useless.

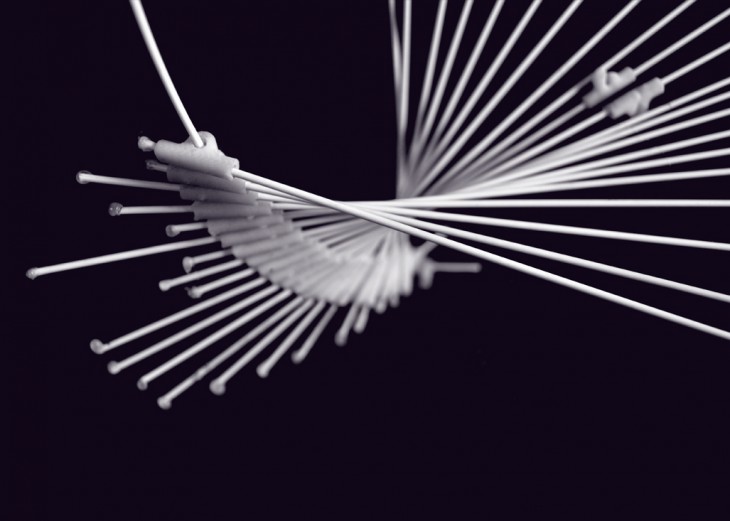

To overcome this problem, we decided to create the desired flowing surface by stringing the rods between two spines. This was successful, and provided us with a malleable, flowing surface, whose stiffness maintained its shape and form, but small movement through multiple pieces had the residual of a graceful form.

Connecting to the board was initially intended to be the standard “screw a hole” technique, employed by many. However, after exhausting our supplies of plastic rods, we decided to use our few remaining joints to create the connection to the board. Yes, it does use glue.

The flexible, malleable, adaptable surface was created by something never designed to act as a surface. The possibility of 3D printing has allowed us to join the given material – plastic rods – into a graceful sculpture.