The exercise aims to understand the various aspects of milling machine, the ability for it to make an architectural detail and to understand its constraints on design. Focusing on the use of milling tools in order to get specific forms, the exercise was to design a hexagonal tile of size that would be tangential to the points given so as to create a seamless repetition of patterned designs thus the pattern should allow rain water to flow seamlessly in order for it to make its way out of the pattern.

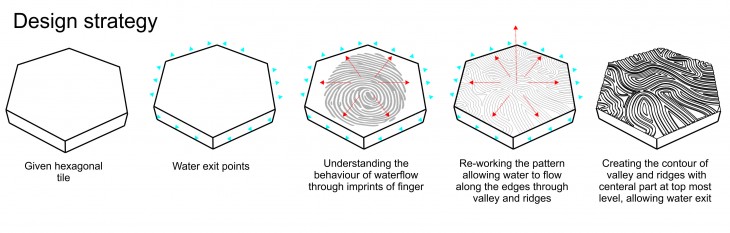

Design:

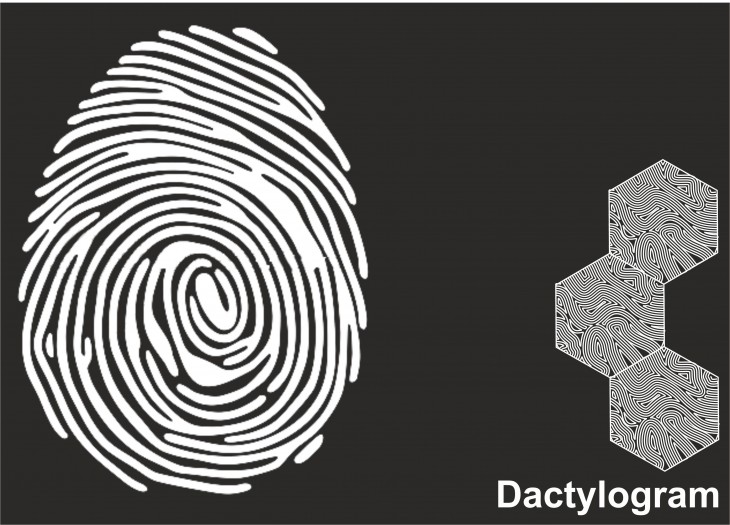

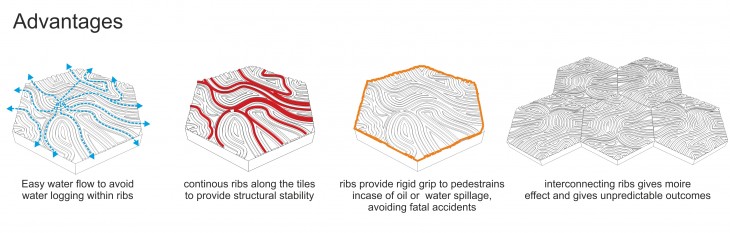

The concept and the goal of the pattern is to create a seamless flow on organizing curvilinear lines, this is achieved by the use of different levels of curvilinear pattern linked to each other, it is derived and inspired from a series of abstract patterns that were extracted to study water flow thus from diverse animal patterns seen on different kinds of animals and organisms. This pattern works as rainwater collector diverting excess water to a specific area when interconnected for the reason that each lines are levelled up to bottom, sloped gradient from higher centre of tile to the lower edges. Coming from the middle point of the tile, when channelled to each other it creates a slide through and through, so that water are collected into a specific area. The extruded lines also creates a rough surface that has the capability to trap dirt, for safety reason the pattern is designed as a non slip surface.

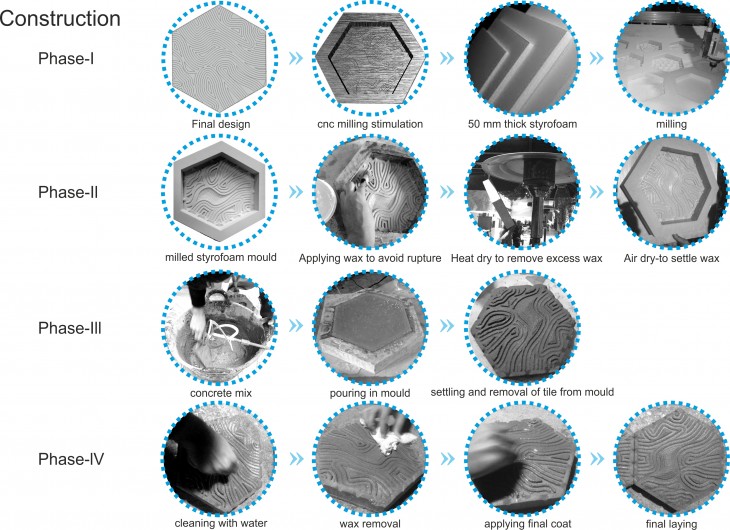

Process:

The process initiated various curvy linear lines within the hexagon and whereby understanding the flow patterns, further this lines arranged at different levels to get a clear idea of water flow, then with the help of 3d modelling various curves were examined and its flow were studied. This patterns were tested with the help of CAD-CAM stimulation and milling tools, giving a clear idea of actual formations. Hence a final prototype was derived through it and milling G-Code were exported. This G-codes were feuded in milling machine. The milling was done on 50mm Thick Styrofoam. Through intensive milling, a foam mould for casting tiles was produced. In order to cast a concrete tile the mould surface was finished with Vaseline so that the concrete won’t stick to the mould and multiple tiles can be produced through single mould. Further it was poured with concrete and dried for 12 hours. The tile was taken out from the mould and settled for another 12 hour in order that it is completely dried out. The process was repeated and multiple tiles were casted. The Vaseline on tiles was cleaned through water and finally tiles were dried and polished.

Renderings: