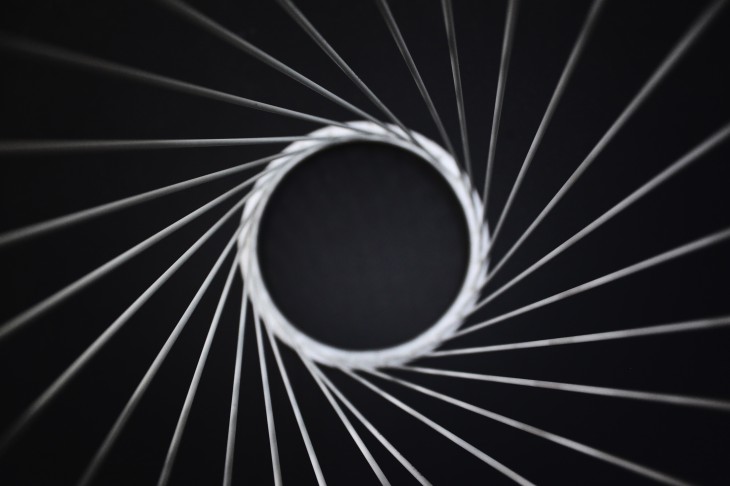

Derived from a hyperboloid of 1 sheet, the Hyperblob is a free standing structure made up of 25 2mm fiberglass rods, 33mm long, through two 3D printed rings, 150 mm in diameter. Hyperboloids can be found in architecture and are based on the concept of a ruled surface: through every point on the surface lies a straight line. Hyperblob is an exploration of curvature through the use of straight lines. The structure has a variety of movements, in all of the cartesian coordinates, due to the 3D printed joints.

The Digital Fabrication world has introduced the magic of 3D printing to a variety of audiences. As students, designers, and thinkers it was our task to explore this new technology and create a joint was only possible using this process. Using this criteria we produced a repetative joint that comprised of openings, angled at 20 degrees, as well as a bi-axial interlocking connection mechanism. Constrained by a bounding box of 50x50x100 mm, we printed 26 individual joints that when combined form two seperate rings. The Hyperblob comes to life when rods pass through each ring allowing the structure to stand, move, and deform depending on the users manipulation.