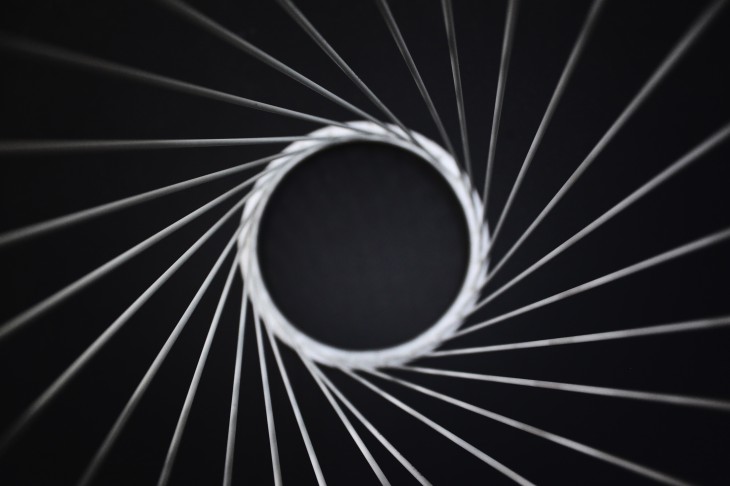

The aim of our notion is to create the state which the model is able to be opened and closed. Have a look at our joints, they are the simplest shape fomed likes circle which there are several holes on it. By these, the rods could be formed into the spiral column, the advantage of the form, it could be changed the form into defferent states by rotating the joint. Firstly, move the joint along the colume shape we created and then push it towards the two seperated joints we fixed on the ground. In this state, the structure will display with fan-shaped. Secondly, having rotating the joint, the middile area will be opened likes the shell movement.

Shell Structure Testing

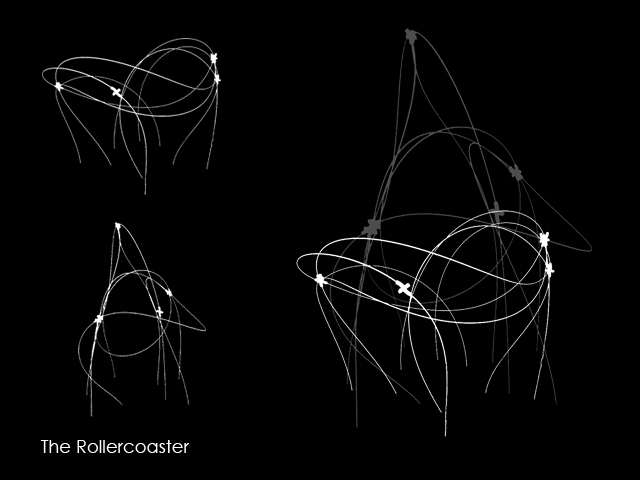

Digital Fabrication – 3D Printing – The Rollercoaster

The idea of Rollercoaster was to achieve two configurations by sliding and locking into position the joints fabricated in the 3D printer. Four joints were created by twisting a pipe which would be joined with itself to create different angles of sliding as well as different amounts of cables running through. This joints would then be coupled with each other by a female-male joint that, aided by the tension of the wire, would lock in place. The different configurations would be achieved by clipping different joints together and sliding the wires to change the inflection point.

DIGITAL FABRICATION PRESENTATION – Laser Cutting

On the 6th of November the Digital Fabrication Seminar, tutored by Edouard Cabay, Alexandre Dubor, Anastasia Pistofidou and Chirag Rangholia, presented their Laser Cutting works before the Seminar tutors, IAAC MAA Director Areti Markopoulou and IAAC Academic Coordinator Silvia Brandi, as well as special guest Juan Pablo Quintero from MedioDesign Barcelona, presenting 1:1 scale tower installations in the IAAC Courtyard, giving life to the courtyard garden.