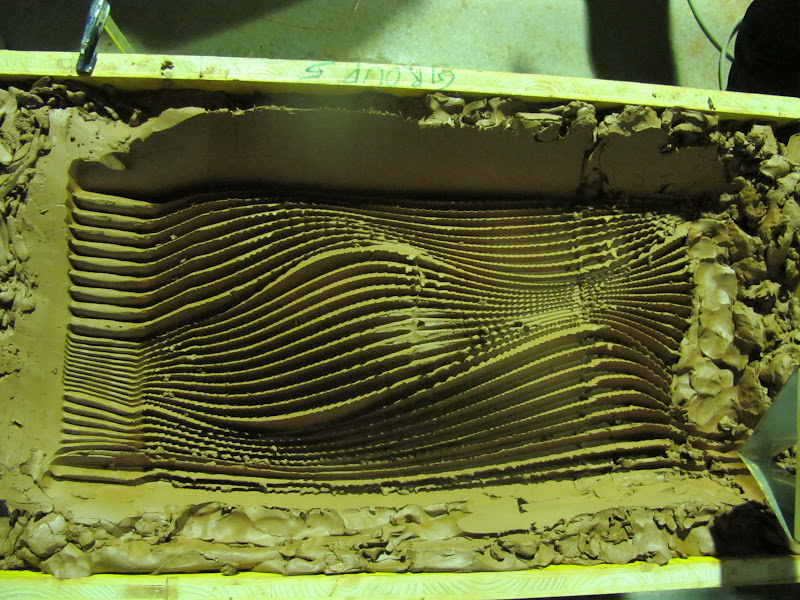

The students presented their outcomes out of the experimentation that they had with clay and Kuka Robot from the MAA seminar with Michael Knauss and Mirjan Ammar. Most of the teams were working with compression techniques to form their clay mold so as to cast concrete. Each group fabricated their own tool that they adjusted with the Kuka robotic arm. Working with digital models for the positive and negative design for the mold and the cast, students had to deal with information coming out from the tool geometry and material properties. Pressure techniques leaded to material displacements that needed to be taken into account, while other teams worked with material extraction.Following the above different process’s, a variety of results was delivered.