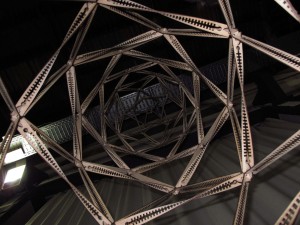

Triagon is a combination of triangles and a penthagons coexisting in the same structure.

The goal of this first Digital Fabrication project was to build a tower out of 4 board of 3mm plywood while exploring the properties of the material and to acquaint ourselves with laser cutting.

The Triagon stands 2.7m tall. The structure is made out of a single 180° twisted plywood elements which works in tension along with the joints to form an equilateral triangle which is the basic unit of the tower.

Remita Thomas /Rodion Eremeev / Alejandro Martínez del Campo

We began with triangles as the basic geometry of our structure because of its stability. After inicial testings of the possible joinery with cartboard and plywood we realized that a combination of circles and rods would be the most efficient design for our conections.

Later on we wanted to play with the properties of the material, so we started bending and twisting the rod, which generates stress on the joints and makes the basic unit more robust. In order to twist the rods 180° we had to use another technique which involved wetting the plywood so that it became more elastic and cuting inside the rod a dentate form with circular ends to prevent breakage. We also found out that rods needed to be cut in the same directions of the fibers so that the twisting could be achieved.

To minimize the waste of the material and the cutting time we used just 2 elements in the whole structure, one was the 30cm rod itself and the other was the circular conections which we also used for attaching the tower to the base.