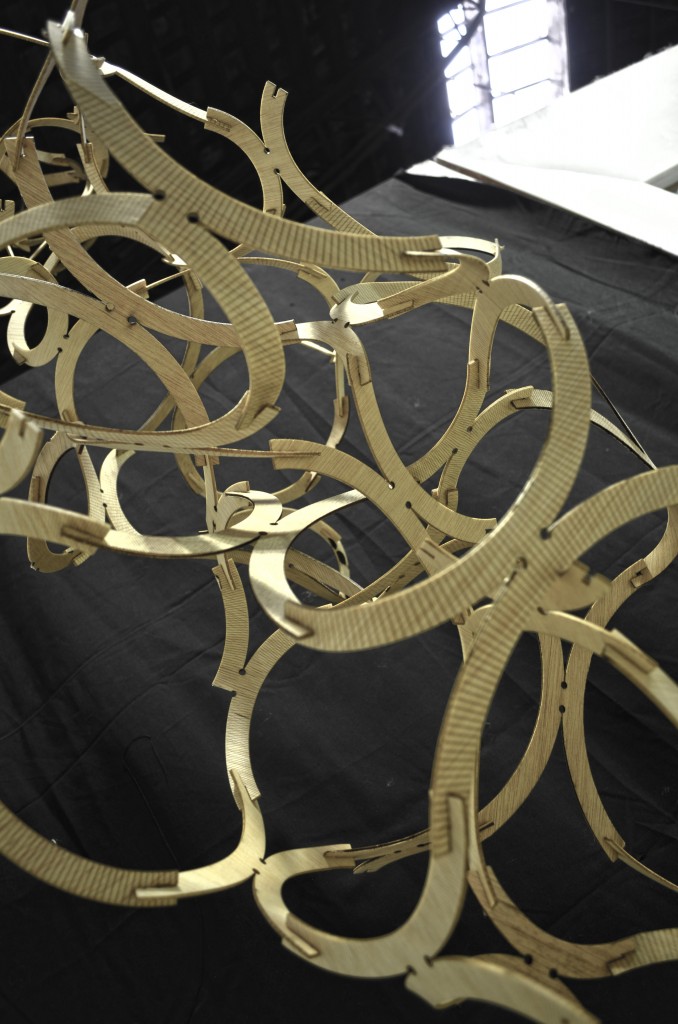

The initial idea was to cut the wood in strips and develope a three-dimensional structure by joining them, in order to minimize wastage and take advantage of the natural properties of plywood. The concept stems from native basket weaving techniques which can be used as a structural system to develope different kind of three-dimensional volumes. Firstly, we experimented the material properties for warping, bending, joining and twisting. We tried strips with different lenght, width and fiber directions to find the best performance of the structure. After assembling the main grid, we reinforced the tower with longer pieces gradually. We discovered that the joinery we designed gave the structure possiblity to grow in height by pulling it in the longitudinal axis, and the diameter was contracted. We could get the opposite effect of expansion of the diameter resulting in a shorter tower. The form has the flexibilty of changing the shape without any adverse effect on the structure.

500 Joints High Tower

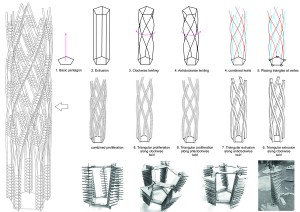

PROLIFERATIVE_TWIRL

The project initiated with the pentagonal base-sides 30 cm (given). The very idea of understanding the properties of 3 mm thick plywood i.e bending, twisting, stretching etc through the joinery details. Read More

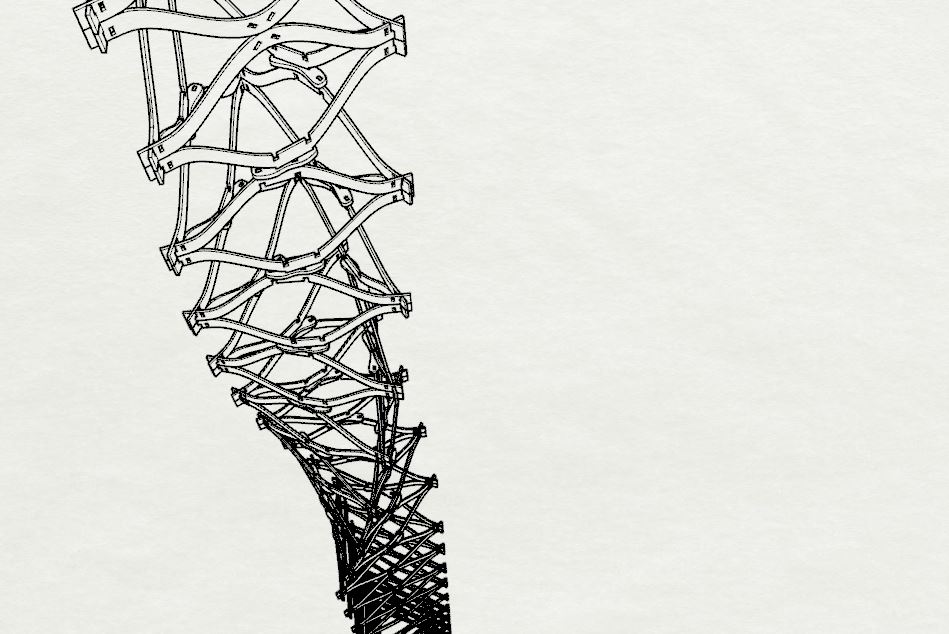

Turning Torso

The design of our tower was driven by several criteria: || maximization of material usage

|| repetition of a single member

|| achieving of several possible configurations

As a result of a successful implementation of the first and the second criteria, we were able to make use of 97% of the available material, consequently reaching the height of nearly 5 meters in the virtual model simulation. Nevertheless, the height of the virtual model was modeled in the “perfect world” conditions, thus not reflecting such important physical criteria as material stress capabilities and the vertical load distribution in a structure of this type. Having assembled several sections of the tower into their envisioned arrangement, we confirmed that such material as wood fails in direct correlation with the grain its cut along and the amount of stress it experiences in the thinnest joinery areas. We realized that in order to reduce the stress||strain loads in our tower we need to drastically reduce the total height of the structure and hence tackle the third design criteria, multiple configurations using a repetitive single element.

Bloom

The exercise was to design a vertical structure consisting of different kinds of connections with wood material. Our goal was to use the necessary number of vertical joints that accentuate the curvy figure of our structure… and of course, aim higher!