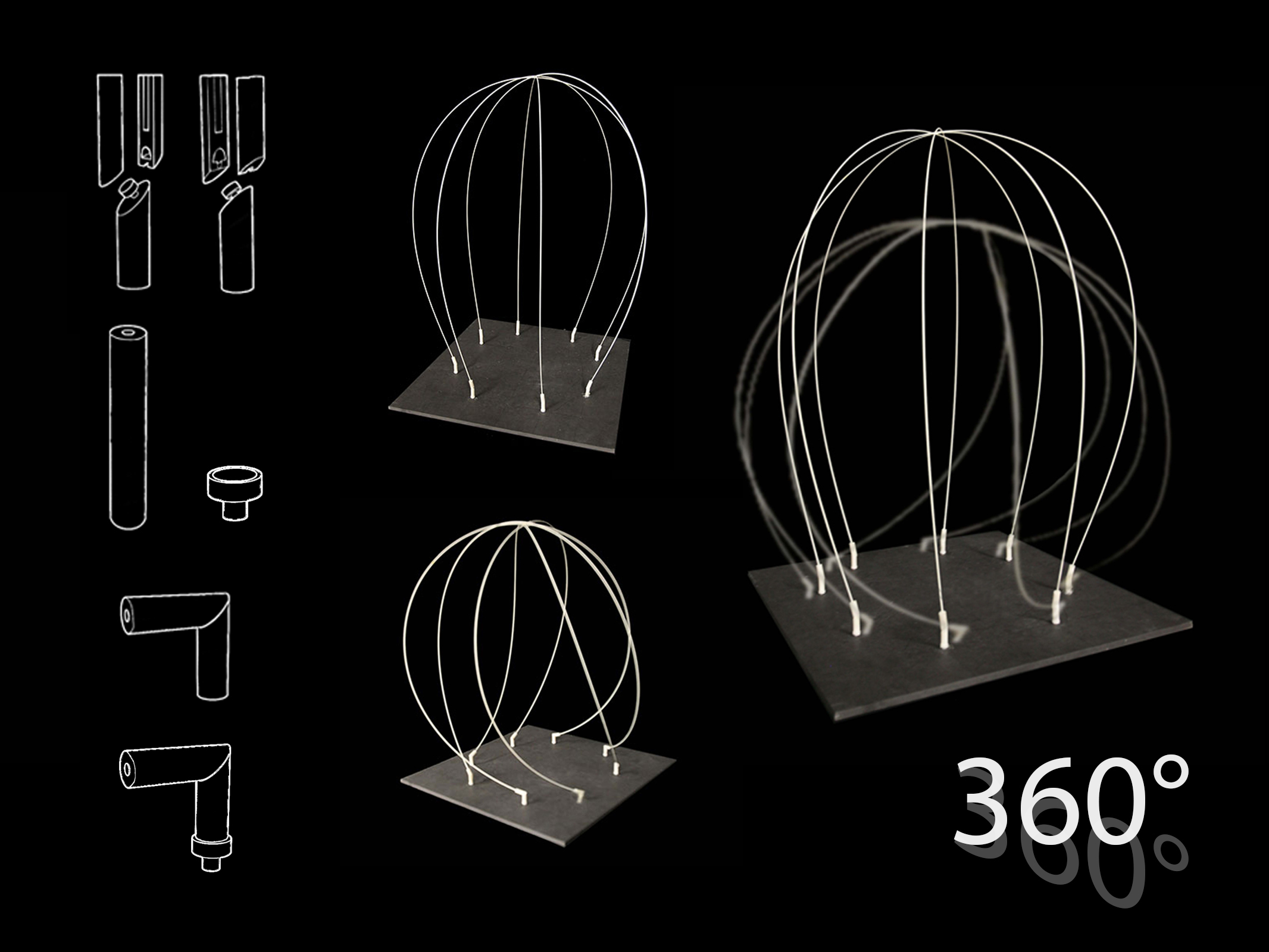

The goal of the 3d printing exercise was to create a dynamic assembly of plastic rods that will be connected with each other using a 3d printed component. The resulting structure should take advantage of the properties of the materials and use that to create movement and interaction.

The goal of the 3d printing exercise was to create a dynamic assembly of plastic rods that will be connected with each other using a 3d printed component. The resulting structure should take advantage of the properties of the materials and use that to create movement and interaction.

cube∞

360°

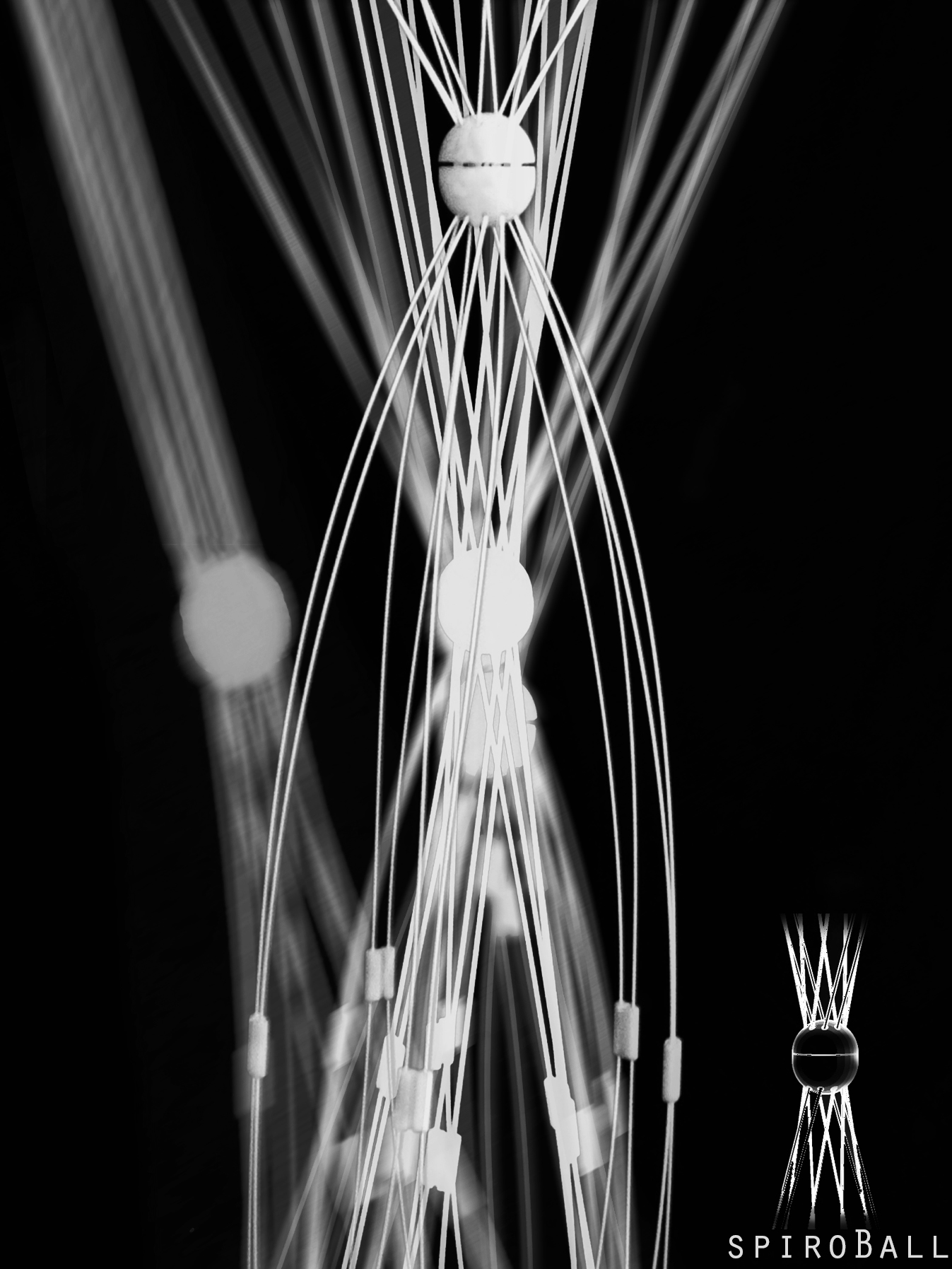

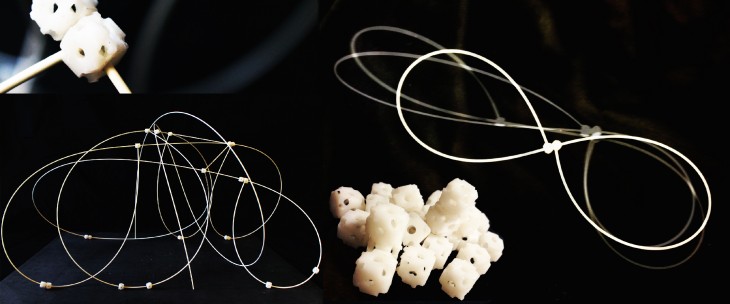

The Spiroball

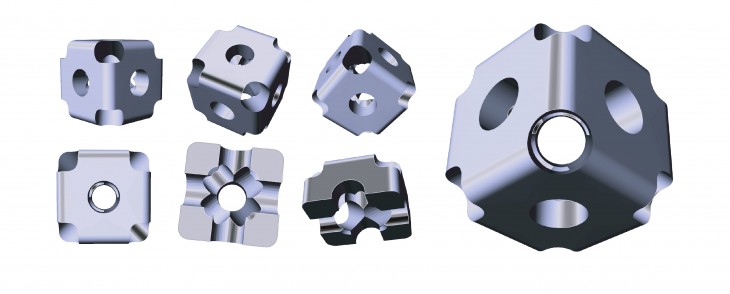

The basic concept behind the whole design was to have dynamism in a vertical design by using one single element, and the possibility of this element to either move in the vertical axis so as to either merge the vertical rods inwards or expand them outwards or rotate the element in horizontal axis creating a spire effect in the vertical rods. Read More

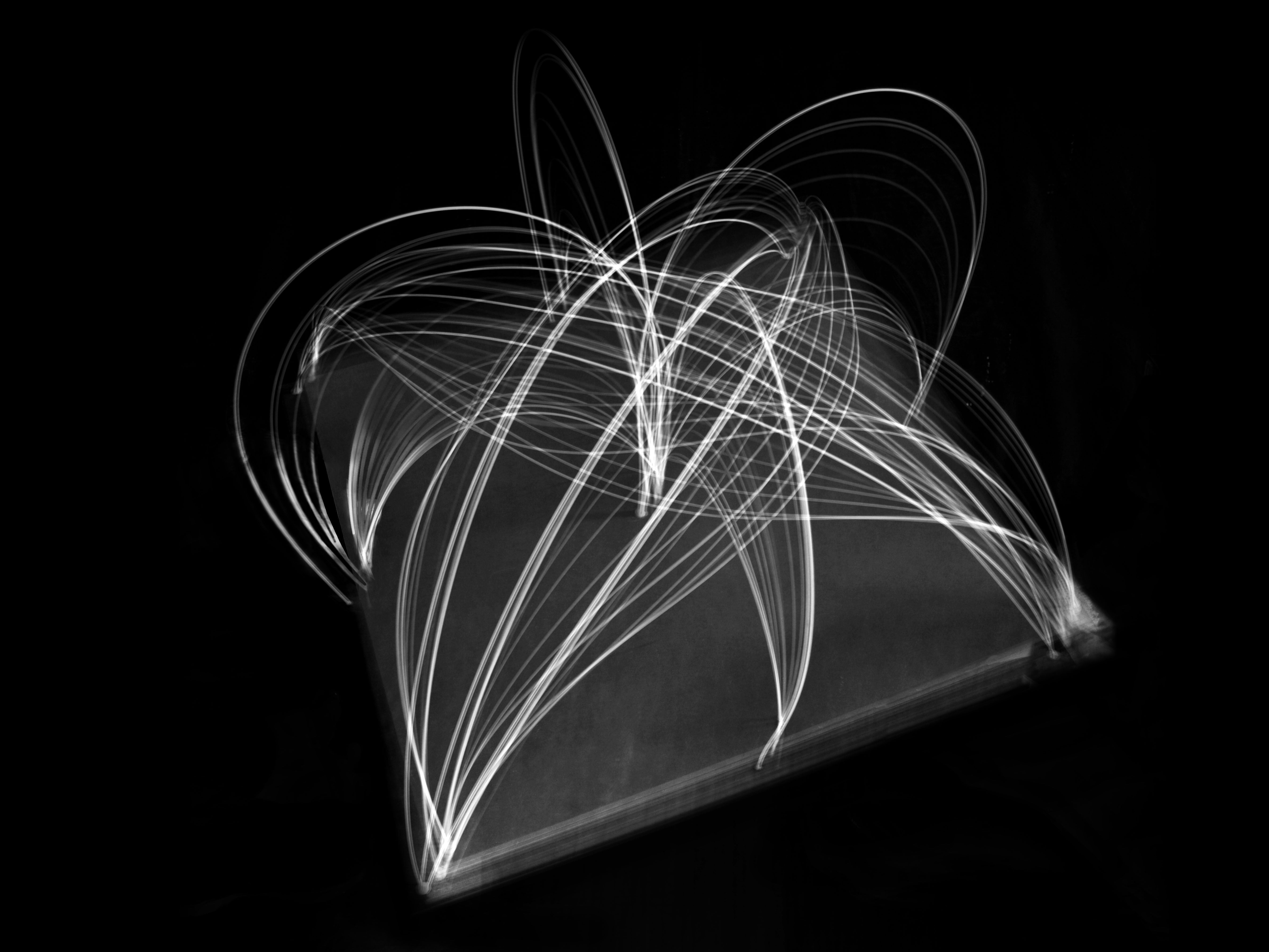

Moving10

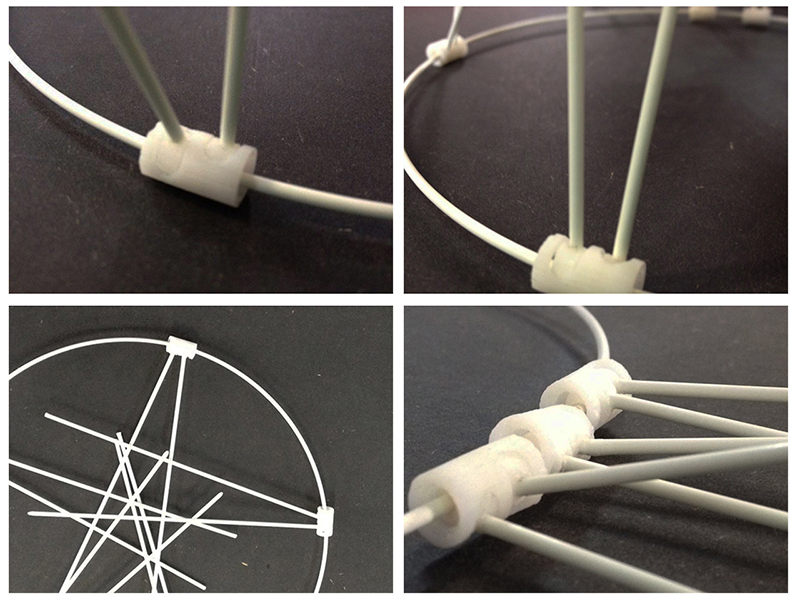

The primary goal was to design a kinetic structure that is supported by crossing elements of the same material to each other. This ultimately created a self supported free standing structure with the help of crossing components.

We created several axes by grouping rods together to make the flexible components more durable. To achieve a durable structure that would support itself, we used two three-pieced rods and one four-piece rod. We joined all of these elements with by designing 3d printed joints. Read More

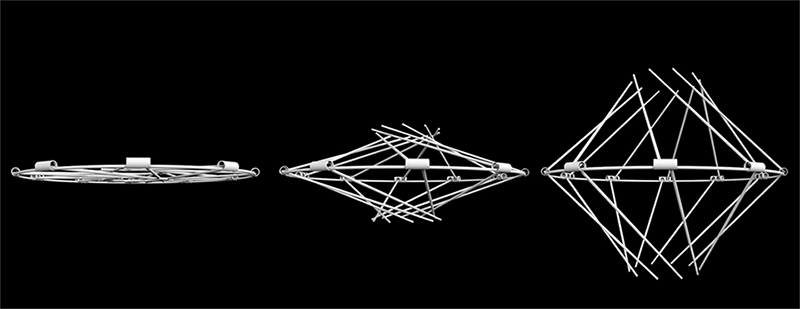

The Disk

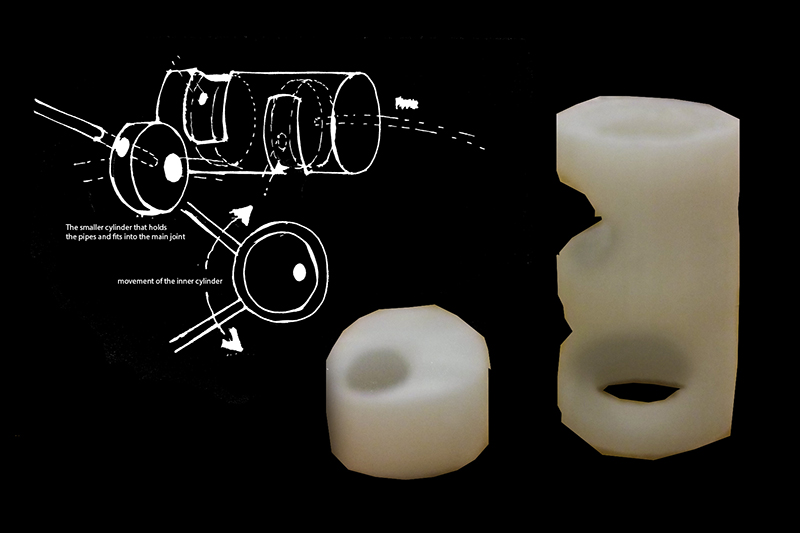

Our line of thought was to design a joint, which had the ability to move within itself and control the motion of the resultant structure and not just provide the structural support. The exploration trials were of the various possibilities in which the motion of the joint was the result of the structure to be designed and not the structure as the resultant of the joint.

In the final design, the bending properties of the pipe were used in the form of a circle that gives the circular form to the entire structure. The 3D printing technology gave us the chance to explore Joints which could result in dynamic changes in the form of the structure.

A flat disk opening out into a complete cylindrical structure.